We obtain many resources from the earth—water, food and clothing as well as raw materials such as rubber, resin, and metal. At the same time, we inflict damage on the earth through the emission of greenhouse gases and depletion of resources as a result of overuse in our daily lives and business activities.

To leave a rich, green earth to the children who will build the future, Toyoda Gosei has been implementing Environmental Action Plans every five years. We have also formulated a long-term vision in our TG 2050 Environmental Challenge and are working to preserve the environment. These activities have earned Toyoda Gosei a high ranking by the press and others, and we will further intensify our efforts. We will also continue working actively to create a corporate culture and develop personnel for the implementation of sustainable environmental preservation activities.

Contributing to Environmental Preservation Through All Our Business Activities

Basic philosophy

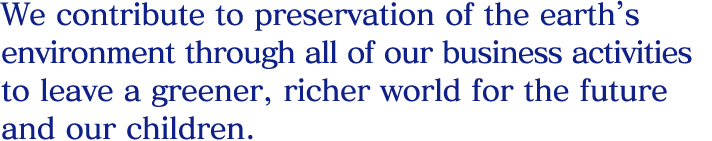

The Toyoda Gosei Group formulated its 1st Environmental Action Plan in 1993 based on its environmental policy, and since that time has been actively confronting environmental issues.

With the belief that environmental issues need to be tackled from a long-term perspective, we announced the TG 2050 Environmental Challenge, our long-term environmental targets, in February 2016. That same year we formulated our 6th Environmental Action Plan for activities and targets over the five years until 2020, and have been promoting environmental activities.

To carry out environmental management that meets the expectations of society, we have established environmental operations in the Americas, China, and Asia, and have put in place a global system for area management in these four global regions including Japan. To achieve our TG 2050 Environmental Challenges, we are implementing group-wide activities to meet FY2020 targets with a view to the medium term until 2030.

1. Environmentally-friendly corporate activities

We are keenly aware that all stages of our business relate deeply to the environment, from development, production, and sales activities to end-of-life disposal. The Toyoda Gosei Group, including all internal departments, domestic and international affiliates, and suppliers, conducts all business activities with concern for the environment in cooperation and coordination with customers, government authorities, and others.

2. Good corporate citizenship

As a good corporate citizen, we participate in, support, and cooperate with environmental activities by many groups while also working on environmental activities in the community and broader society. We also provide education for all employees to support them in becoming involved in environmental activities as members of the community and society, and support social contributions and volunteerism.

3. While spreading information on these activities, we listen to the opinions of people at all levels of society and work to improve our activities wherever we can.

TG 2050 Environmental Challenge —A Greener, Richer World for Our Children

The Toyoda Gosei Group specializes in the field of high polymers—rubber and plastics.

Our symbol is the benzene ring, a hexagonal hydrocarbon structure that is the starting point for polymers. Borrowing from the six sides of the benzene ring, the TG 2050 Environmental Challenge sets six challenges to strengthen our environmental efforts with a long-term view to the year 2050.

TG 2050 Environmental Challenge (Six Challenges)

Efforts to date

- *1 Registration, Evaluation, Authorization and Restriction of Chemicals Chemicals

- *2 Substances of Concern

- *3 Volatile organic compounds

- *4 Pollutant Release and Transfer Register

- *5 Hydrofluorocarbons (HFC), perfluorocarbons (PFC), sulfur hexafluoride (SF6), methane (CH4), nitrous oxide (N2O)

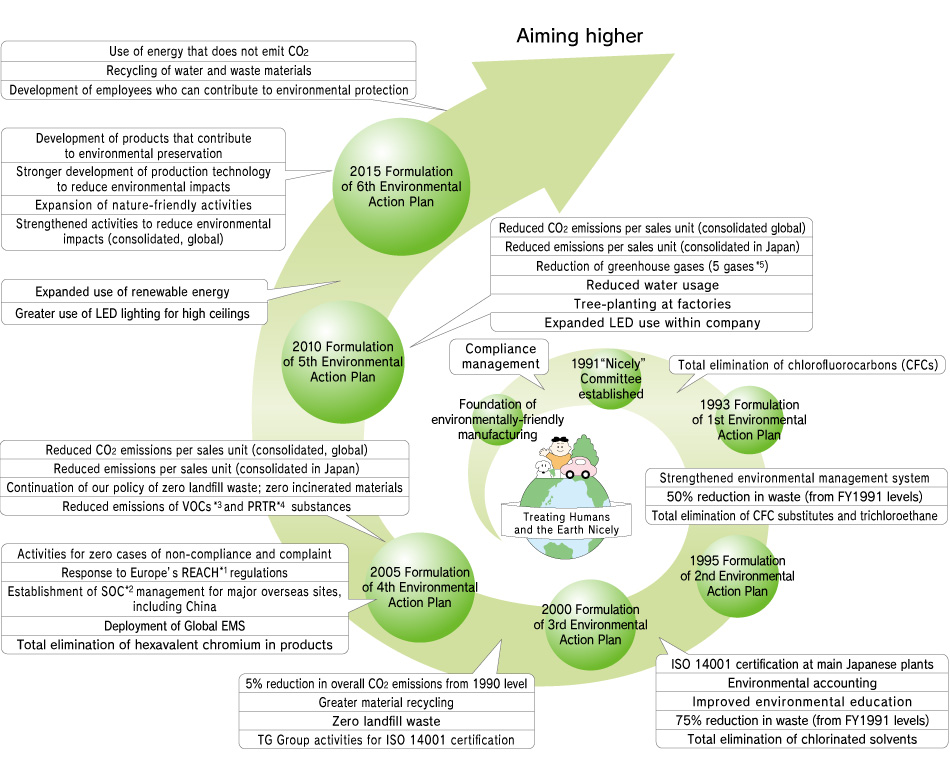

Environmental organization

Our medium- and long-term policy and key action items are discussed and decided in an Environmental Committee chaired by the company president. The Environmental Committee consists of four subcommittees in the areas of products, production, and quality. The subcommittees are further broken down into working groups that promote and manage areas such as reductions in energy use, waste products, and VOC emissions, and preservation of the environment. In this way, environmental preservation and management activities are conducted from an expert perspective.

Liaison committees have also been established to share information with related companies in Japan and abroad.

■Environmental organizational structure

Risk and opportunity associated with climate change and resource depletion

We view the risks and opportunities related to climate change and resource depletion as important management issues. We are working to strengthen our response to financial risks, risks to society overall, and risks to suppliers, such as effects on the economy and production activities from severe weather abnormalities, changes in rainfall patterns, droughts and floods, from a global perspective based on laws, regulations and trends.

| Risk | Opportunity | |

|---|---|---|

| Climate change | Cost increases from carbon tax and soaring energy prices | Development of lighter weight, next-generation automotive parts Cost reductions from efficient energy use |

| Resource recycling | Effects of water shortages and floods on production activities | Cost reductions from re-use and decreased use of water |

| Cost increases from difficulty in procuring materials, soaring material prices | Cost reductions from recycling technology, use of fewer materials | |

| Management (regulatory compliance) |

Loss of trust in the company due to environmental problems, including legal violations, and insufficient efforts to protect the environment. | Raise brand strength by enhancing environmental activities |

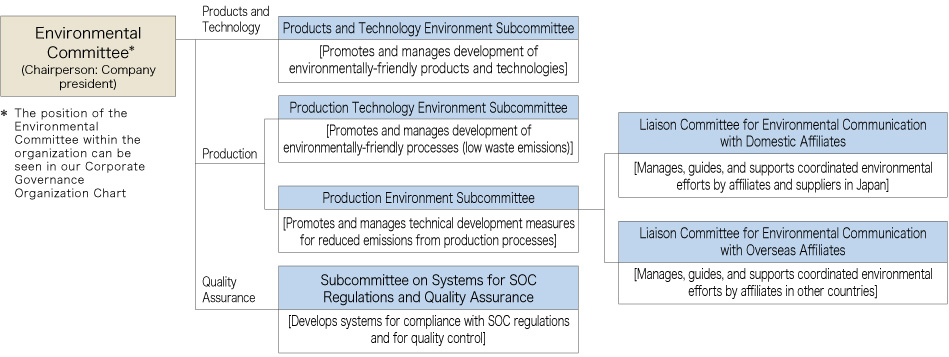

Resource utilization and environmental emissions in business activities

To lessen the amount of energy, material and other resource inputs, and maximum product output, we are utilizing our skills in product development, process development and workplace kaizen in efforts to improve through business activities.

The input resources we use include environmentally friendly materials and clean energy.

Environmental impact in the value chain

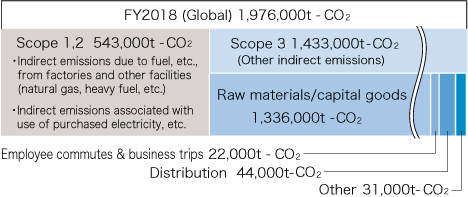

From the perspective of preserving the earth, we have surveyed and disclosed not only GHG emissions (Scope 1*12, Scope 2*13) in our business activities but also emissions in our entire value chain including excavation of raw materials and product use and disposal (Scope 3*14). To increase precision for a more accurate picture, we reviewed the calculation method and data collection for Scope 3.

- *12 Greenhouse gas emissions directly emitted by companies themselves (fossil fuels, natural gas, etc.)

- *13 Greenhouse gas emissions that are indirectly emitted (purchased power, etc.)

- *14 Greenhouse gas emissions indirectly emitted by companies in the supply chain (raw material production, transportation, business trips, commuting, etc.)

■CO2 Emissions by Scope Leve

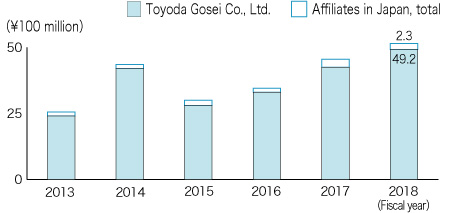

Environmental Protection Costs

Toyoda Gosei accurately monitors costs incurred for environmental protection in our business endeavors, and conducts appropriate environmental protection activities.

In Toyoda Gosei’s FY2019 environmental protection costs, priority is placed on research and development, business areas (switch to LEDs for high-ceiling lighting, recycling, greenhouse gas reductions), and social activities (Plant Afforestation). The economic effects include reduced waste disposal costs with measures to reduce waste production and increase waste recycling, thorough daily kaizen in workplaces, and lower electricity costs with increased efficiency in utility equipment.

■Environmental Protection Costs

(Unit: \100 million)

| Type of cost | Toyoda Gosei | Affiliates in Japan, total |

|---|---|---|

| Research and development costs*15 | 12.1 | 0 |

| Costs within business areas*16 | 33.5 | 2.0 |

| Management activity costs*17 | 1.4 | 0.2 |

| Social activity costs*18 | 2.1 | 0.1 |

| Environmental damage costs*19 | 0.1 | 0 |

| Total | 49.2 | 2.3 |

- *15 Costs for research and development of products that reduce environmental impact

- *16 Costs to reduce environmental impacts from production, including pollution control, reduced energy consumption, and waste disposal.

- *17 Costs for management, including education, maintenance of the environmental management system, and measurements.

- *18 Costs for such measures as tree-planting and beautification.

- *19 Costs for dealing with environmental impacts from business operations.

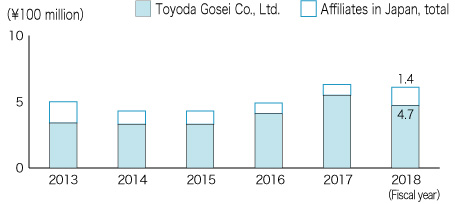

■Economic effect*20

(Unit: \100 million)

| Item | Toyoda Gosei | Affiliates in Japan, total |

|---|---|---|

| Energy expenses | 1.8 | 1.3 |

| Waste-processing expenses | 2.9 | 0.1 |

| Total | 4.7 | 1.4 |

- *20 The economic effects calculated here are those that can be ascertained based on solid evidence.

■Quantitative effect*21

| Item | Effect |

|---|---|

| Global warming prevention (CO2 reduction) | 6,393t-CO2 |

| Waste reductions (amount reduced) | 1,391t |

| Legal compliance |

- *21 Amounts are calculated for Toyoda Gosei alone.

Environmental Data

- Contributing to Environmental Preservation Through All Our Business Activities

- Sixth Environmental Action Plan Activities and Results

- Building Low-Carbon Societies

- Building Recycling Societies

- Environmental Preservation and Building Environmentally-Friendly Societies

- Environmental Management

- Environmental Efforts at Affiliated Companies

- Environmental Data

- Third-Party Verification

- Third-Party Assessment