Environmental management

While working for environmental preservation, we are continuing employee training and education programs so that every employee can act with a wareness of the environment.

Basic philosophy

Toyoda Gosei will do its utmost to raise the environmental awareness of employees and train personnel for sustainable environmental activities.

Enhancing Group-wide environmental management

Environmental activities

The entire Toyoda Gosei Group promotes environmental management. Environmental data has been collected by domestic affiliates since FY2001 and by international affiliates since FY2003. Based on these environmental data (CO2 emissions, waste, water usage, VOC emissions, and more), we set annual targets and promote reduction activities every year. In FY2018, we worked closely with Group companies.

■Production sites targeted for environmental activities

| Toyoda Gosei | Affiliates in Japan |

|---|---|

|

|

| Overseas Affiliates | |

|

■Americas〈 Regional headquarters: Toyoda Gosei North America Corporation〉

■Asia〈 Regional headquarters: Toyoda Gosei Asia Co., Ltd. 〉

■China〈 Regional headquarters: Toyoda Gosei (China) Investment Co., Ltd. 〉

■Europe and Africa

|

|

- Acquired ISO 14001 certification. New companies and main plants aim to acquire ISO 14001 within three years of starting operation

Development of environmental management systems with international affiliates

Internationally, we established environmental management functions in the China region from 2010, the Asia region in 2014, and the Americas region in 2015, and have been strengthening our management systems. In FY2018, we started regular teleconferences with regional headquarters Toyoda Gosei Asia Co., Ltd. in Thailand to share information and further strengthen cooperation.

Start of “Regular Environmental Management Liaison Meetings" in Asia

Regular Environmental Management Liaison Meetings have been held with Toyoda Gosei (China) Investment Co., Ltd.*2 in the China region since FY2013, and with Toyoda Gosei North America Corporation in the Americas since 2016. They have now been started with Toyoda Gosei Asia Co., Ltd. The main aims are openness and timely collection of area information, and exchange of opinions to raise staff levels.

- *2 In FY2013, Toyoda Gosei (Shanghai) Management Co., Ltd.

environmental surveys

Audit of whether environmental management systems are operating properly.

■ISO 14001 environmental audit

Toyoda Gosei and our domestic and international affiliates have acquired ISO 14001 certification for our environmental management systems. Internal environmental audits are done by teams composed of members from outside the workplace being audited to raise the independence and objectivity of the audit. Toyoda Gosei Co., Ltd. also requests external environmental audits from the Japan Quality Assurance Organization (JQA), and our environmental management system conforms with ISO14001 to ensure proper operations.

■ISO-certified production sites

| Toyoda Gosei | 10 plants*3 (FY2018) |

| Affiliates in Japan | 9 companies |

| Overseas Affiliates | Americas: 12 companies, Asia: 7 companies, China: 6 c ompanies, Europe/ Africa: 3 companies |

- *3 The business of three plants owned by Toyoda Gosei in Kyushu (Fukuoka Plant, Saga Plant, Kitakyushu Plant) was transferred to a subsidiary established in Kyushu (Toyoda Gosei Kyushu Co., Ltd.) (April 2019). Currently, 7 factories.

-

External environmental audits/ Morimachi Plant

External environmental audits/ Morimachi Plant -

Internal environmental audits/Ogawa Ind. Co., Ltd.

Internal environmental audits/Ogawa Ind. Co., Ltd.

■International environmental audits

In FY2018, we conducted voluntary inspections based on the TG Global EMS and conducted genchi-genbutsu environmental audits at important sites.

Corrective measures have been completed for all of the points needing improvement identified in these audits.

-

TG Missouri Co., Ltd.

TG Missouri Co., Ltd. -

Toyoda Gosei Rubber (Thailand) Co., Ltd.

Toyoda Gosei Rubber (Thailand) Co., Ltd.

Activities to eliminate compliance and environmental violations and complaints

In addition to strictly complying with all laws and regulations, we have special departments that conduct periodic environmental inspections and maintenance to prevent environmental problems and complaints from occurring. To counter risks, we also carry out preventive activities such as environmental conservation working groups. Cases of failure at other companies are analyzed, and similar facilities, both those at domestic and international affiliates, are inspected to prevent the same failures.

In FY2018, we had no environmental problems or complaints (Toyoda Gosei: 0 cases, Japan: 0 cases, other countries: 0 cases). We will continue to strengthen our prevention activities for environmental risks.

Proper disposal and storage of PCB-containing equipment

The law stipulates that hazardous and persistent PCB (polychlorinated biphenyl) waste must be disposed of by the end of March 2027. We started outsourcing this disposal in FY2006 and are proceeding appropriately. By FY2018, 848 units had been processed.

We will continue to process untreated low-concentration PCB waste at an early stage. Until that is completed, appropriate management based on the PCB Special Measures Law is in place to prevent the risk of runoff and soil contamination.

| Category | Type | No. of units treated | Treated weight |

|---|---|---|---|

| High concentration PCB waste material (PCB levels: >5,000 mg/kg) |

Ballast, power capacitors, etc. | 795 units | 6.8t |

| Low concentration PCB waste material (PCB levels: 0.5-5,000 mg/kg) |

Transformers, power capacitors, etc. | 53 units | 73.9t |

-

Treatment of PCB waste

Treatment of PCB waste

Protecting soil and groundwater

We carefully monitor and treat soil and groundwater contamination from toxic substances such as trichloroethylene, which was formerly used in cleaning agents. We have established observation wells at each plant, and regularly confirm that there is no soil or groundwater pollution from toxic substances and oils.

| Location | Target | Status of corrective measures |

|---|---|---|

| Haruhi Plant | Groundwater | Purification in progress (proactive treatment, as contamination from off-site sources is possible) |

| Inazawa Plant | Groundwater | Because substances we have no history of using have been detected, regular reports to the government contain results of measurements only * Results below reference values since 2010(government reports concluded in FY2012) |

Enhancement of global employee training and education

Environmental education

Toyoda Gosei educates employees on environmental problems including the destruction of nature and environmental pollution, the impacts on the environment of production activities, and compliance with environmental regulations. The content each year emphasizes understanding and practices based on legal trends, with examples incorporated to create specific and understandable teaching materials.

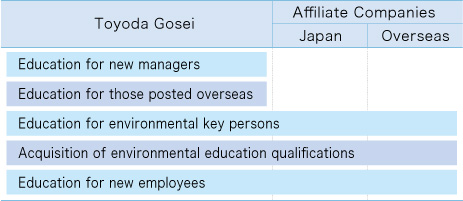

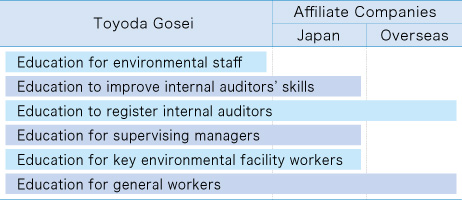

■Environmental education system

Level-specific training

ISO Education

■Education to improve skills of environmental staff

Through TG Global EMS and monthly reports, we conduct training to improve environmental skills to share viewpoints and examples of environmental load reduction and improve knowledge of environmental management work.

In FY2018, medium-term CO2 reduction targets were shared and training to improve environmental skills was conducted in May for environmental managers at regional headquarters Toyoda Gosei (Shanghai) Investment Co., Ltd. (China) and Toyoda Gosei North America, Inc. (Americas). In October, we participated in the annual environmental staff meeting of the China Environmental Committee and provided training on compliance management for the elimination of environmental problems. Going forward, we will continue to promote environmental education centered on the staff at key environmental management locations.

Site inspection for case of reduction (Inazawa Plant)

Site inspection for case of reduction (Inazawa Plant) China Environmental Committee

China Environmental Committee

Activities to raise environmental awareness

We are attempting to raise the environmental awareness of employees through Environment Month events, regular environmental lectures, and other activities so that all employees have an awareness of the environment in their activities for ongoing environmental protection.

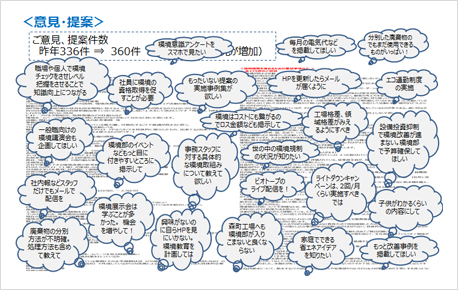

We also conduct a questionnaire survey of employees each year to assess their environmental awareness and plan educational activities based on the results.

Environmental exhibition (Environment Month)

Environmental exhibitions are held to promote environmental conservation activities. In FY2018, we showed domestic and international cases such as development of production equipment and production technologies for more compact and energy efficient processes, and reduction of waste through improvements at factories and easy-to-recycle product designs. In addition, there were videos and panels showing the need to engage in activities for living with nature, Toyoda Gosei Group activities, and our vision for FY2050. This year, under the theme of "Thinking about wastefulness," we introduced our efforts to reduce waste in energy, resources and time, not only at production sites but also in administrative and engineering offices, as well as the approximately 460 proposals for improvement that were submitted. For distant sites, a “Traveling Environmental Exhibition” showing the same videos and panels was held at three plants that requested it (Morimachi, Kitakyushu, and Fukuoka Plants).

Eco tour (Environment Month)

Eco tours are held for employees and their families to learn about the environment. In FY2018, the tour visited Chubu Electric Power Co.’s Kawagoe Electric Power Museum Terra 46 as an opportunity to think about the environment from close contact with nature. Participants learned while enjoying images and simulations about limited energy resources and the environment. They also observed wild herons and ducklings at Yatomino Bird Garden.

Mottainai senryu (Environment Month)

With the aim of raising environmental awareness, we sought senryu verses from all employees of the TG Group with the theme of “Mottainai” (“What a waste!) related to energy, resources and time in our surroundings. Representative works were selected in each department and company, and from them six people were chosen for “Excellence Awards.” Submissions were also posted on the company’s internal website to raise environmental awareness.

| Award | Senryu verses |

|---|---|

| Gold Award | Technologies / to not produce waste / are true manufacturing techniques |

| Silver Award | The feeling that / separating trash is a bother / should be thrown out |

| Paperless / this lie / is dispoved by paper | |

| Bronze Award | “Let’s just / print it out” / is out |

| Two-faced / not good for people / good for paper | |

| Special award | Turn out the lights / turn off the air conditioner / disappear |

Environmental forum

Environmental forums are held to raise environmental awareness and promote environmental activities. In FY2018, Dr. Taikan Oki (Special Adviser to the President The University of Tokyo), a leading expert on research into the sustainability of water resources around the world, was invited as a lecturer. He described various examples in connection with the SDGs goals*4 regarding the state of global water shortages and the need for companies to try to conserve water.

- *4 Seventeen goals and 169 targets that the international community (all United Nations member countries) aim to achieve by 2030, so that everyone can enjoy peace and prosperity.

Participants listening attentively

Taikan Oki giving lecture

Environmental awareness survey

Toyoda Gosei Co., Ltd. conducted its third environmental awareness survey of all employees in Japan to assess environmental trends, the level of employees’ awareness of company environmental activities, and whether the efforts in FY2018 were understood and effective. As in the previous survey, employees showed high interest in world environmental problems. Their recognition of the company’s environmental activities was higher than in the previous year but still insufficient, and their environmental awareness tended not to be tied to practice. Based on the survey results, we will implement measures that will lead to concrete environmental activities.

Environmental contribution awards

Toyoda Gosei established an “Environmental Contribution Award” system to raise environmental awareness and promote environmental activities. Prizes are awarded for the most significant results achieved in environmental activities in the categories of manufacturing, engineering/production preparation, and plants/offices at Toyoda Gosei Co., Ltd., and by domestic affiliates.

| Name of award | Department/Plant | Reason for award | |

|---|---|---|---|

| Environmental contribution award | Manufacturing division | IE Manufacturing Division 2 | Promotes facility improvements such as the use of high-efficiency refrigerators and achieved of all environmental impact reduction targets |

| Technology division | SS Engineering Division, SS Development Division | Developed pad damper that achieves both lightweight steering and vibration suppression (contributes to improved vehicle fuel efficiency) | |

| Production engineering division | Production Engineering Management Division | Reduced paint changeover loss with pouch paint supply system | |

| Environmental Management Award | Bisai Plant | Notifies employees about Toyoda Gosei's environmental targets and reduction examples using the Manabiya (“Learning Building,” a permanent experiential space). PR on Toyoda Gosei’s environmental activities to local residents through Green Day | |

| Name of award | Company | Reason for award |

|---|---|---|

| Environmental Superiority Award | Ichiei Kogyo Co., Ltd. | Significantly achieved all environmental impact reduction targets for the second consecutive year. Promotes activities to raise environmental awareness among employees |

| Environmental Excellence Award | Kaiyo Gomu Co., Ltd. | In addition to achieving all environmental impact reduction targets, actively participates in environmental conservation activities in the Choshi River basin and conducts activities to live with nature-in cooperation with NPOs |

| TG Opseed Co., Ltd. | In addition to achieving all environmental impact reduction targets, conducts environmental awareness surveys of employees and conducts original awareness-raising activities based on the results |

Environmental Booth at company-wide Ekiden running race

To build understanding of the importance of environmental activities, we set up an Environment Booth that introduces our environmental activities at various company events. The theme for FY2018 was “People living with nature.” Panels introduced the need for living with nature and the activities of the Toyoda Gosei Group to live with nature (Heiwacho Plant regulating pond biotope completion map, Fujimae Tidal Flat Nature Observation Society, Yatomi Wild Bird Nature Observation Society). Children also caught invasive species. At the company-wide Ekiden running race, an event was held where they picked up biological cards and learned about invasive species.

-

Panel exhibit area

Panel exhibit area -

Insect origami area

Insect origami area -

Carbon offset certificate

Carbon offset certificate

Green curtain contest held

Since fiscal 2013, we have been growing green curtains of bitter gourds and cucumbers to cover the southern walls of factories and homes in order to raise employees' environmental awareness and reduce energy costs in summer. A Green Curtain Contest was continued in FY2018 for the best green curtains. Nineteen companies and 24 offices entered the contest in the Business Division, and 18 people entered in the Individual Division. Two companies in Japan, one overseas, and three individuals received awards.

-

Office category: Seto Plant

- Contributing to Environmental Preservation Through All Our Business Activities

- Sixth Environmental Action Plan Activities and Results

- Building Low-Carbon Societies

- Building Recycling Societies

- Environmental Preservation and Building Environmentally-Friendly Societies

- Environmental Management

- Environmental Efforts at Affiliated Companies

- Environmental Data

- Third-Party Verification

- Third-Party Assessment