Building Recycling Societies

We are contributing to the realization of a recycling-oriented society by effectively using limited resources through the reduction of waste*1 and water usage and the design of products that are easy to recycle.

- *1 We are currently attempting to reduce waste volumes to meet our FY2020 target as we move toward minimization of industrial waste as set forth in the TG 2050 Environmental Challenge.

Basic philosophy

To move closer to the recycling society envisioned in the TG 2050 Environmental Challenge, Toyoda Gosei aims to minimize industrial waste and water usage and we are making every effort to use resources effectively, reducing materials usage and waste volumes through thorough sorting and the design of easily recyclable products.

Frequent water shortages and floods have become a major problem in all parts of the world. We are attempting to identify these risks in every country and region where we have operations while also striving to give back to the community by reducing water usage, recycling water, and releasing cleaner wastewater.

Reduction of waste

Development of product recycling technology

We develop and design easily recyclable products and materials with thought to the entire lifecycle of automobiles. We are also developing recycling technology for waste material. So far we have established recycling technologies for products that use multiple types of rubber and products that use rubber and different materials. In FY2017 we continued our recycling efforts for effective use of resources.

■Development of technology for end-of-life vehicle parts recycling

| Key items | Measures implemented |

|---|---|

| New recycling |

|

| Use of recycled materials in vehicles |

|

| Product design for easy recycling |

|

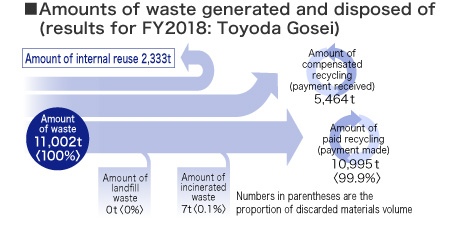

Reduction of waste materials in the production stage

To reduce waste in production processes and achieve our 2020 targets, we are combating waste at its source and recycling.

We have also started a waste reduction project with coordination among plants and production technology, materials technology, and product design departments to strengthen efforts to combat waste at its source. At each plant, we are reducing waste through genchi-genbutsu (go and see), identifying items for reduction with the help of external experts, and implementing rubber, plastic, and liquid reductions.

Study sessions are also held to promote waste reduction at both domestic and international Group companies.

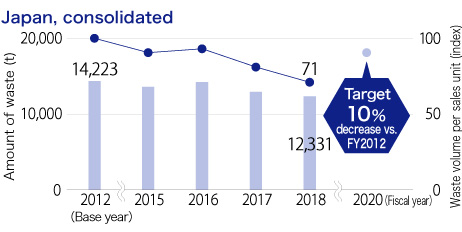

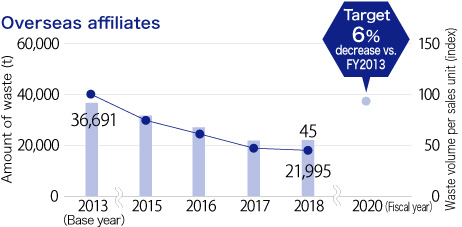

■Waste volume, waste volume per sales unit (index)*2

- *2 The amount of waste per sales unit (index) is

a figure obtained taking the base year as 100

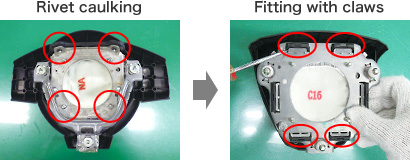

Waste reduction from design of airbag pads that can be easily taken apart*3

Previously, the pad and metal were riveted and caulked. As a result, when there was a problem the product could not be taken apart and it all had to be disposed of as waste, including good components. By switching to a fixation method that allows for easy dismantling while maintaining quality, and for separation of each material component (plastic pad, cloth, metal), waste was reduced by about 8.5 tons as a result of recycling and converting waste into valuables. We will continue reducing waste with similar approaches.

- *3 The ability to easily dismantle various parts

Novelty products using leather scraps

Leather scraps produced at Toyoda Gosei include pieces that have blemishes remaining in the hide. These pieces have been disposed of as waste, but employees proposed producing novelty goods using scrap leather as one activity to reduce workplace waste. Their efforts succeeded in creating marketable products and have led to a reduction in waste.

Reduction of packaging in the distribution stage

In order to reduce the amount of packaging materials used during product transportation, we conduct ongoing reduction activities with a new target set every year. In fiscal 2018, we reduced the packing materials used to prevent contamination by increasing the number of times returnable boxes are washed and keeping them clean. We also reduced the amount of packing materials by attaching lids to returnable boxes.

We will continue reduction activities while considering the balance between maintaining product quality and reducing the amount of packaging materials used.

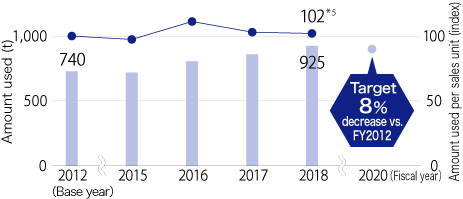

■Amount of distribution packing material used/Amount used per sales unit (index)*4

Toyoda Gosei Co., Ltd.

- *4 The amount of distribution packing material used per sales unit (index) is a figure obtained taking the base year as 100

- *5 The amount of packing material used increased with increased shipments of service parts due to the heavy rains and floods in northern Kyushu in 2017 and western Japan in 2018, and larger part sizes.

Reduction and effective use of water

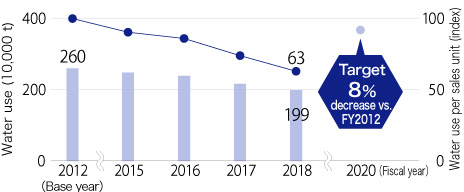

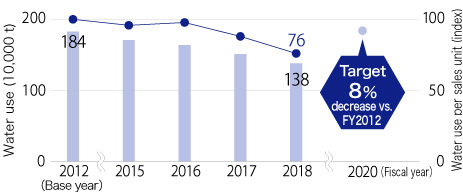

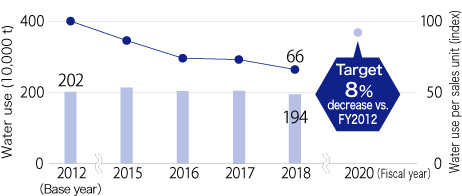

To achieve our 2020 target, we are making improvements through TG ESCO (expert team that conducts reduction activities with genchi-genbutsu [“go-and-see”]). In fiscal 2018, improvements were made in water usage loss and leakage, resulting in a 24% reduction compared to fiscal 2012.

In addition, we are systematically upgrading to wastewater treatment facilities with higher treatment capacity in order to achieve cleaner wastewater and increase the water recycling rate. In FY2018, we upgraded the wastewater treatment facility at the Morimachi Plant. Based on the growing importance of water, we will continue to reduce water consumption and manage wastewater according to local conditions.

■Water use and water use per sales unit (index)*6

Japan, consolidated

Toyoda Gosei Co., Ltd.

Overseas affiliates

- *6 Water use per sales unit (index) is a figure obtained taking the base year as 100

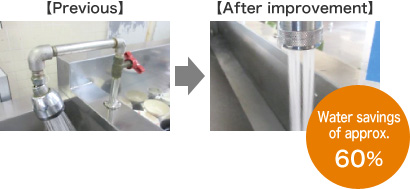

Reduced water use in cafeteria dishwashing

The Morimachi Plant has switched to low-flow, high pressure nozzle heads in the dishwashing area of its cafeteria, resulting in an approximately 60% reduction in water usage. We will continue these kinds of efforts to use water efficiently and decrease water usage.

Reduced water usage with the use of rainwater

Toyoda Gosei Group company Hoshin Gosei Co., Ltd. reduced water usage about 3% by recirculating water in production processes, installing green curtains, and using rainwater to water plants in employee rest spaces.

- Contributing to Environmental Preservation Through All Our Business Activities

- Sixth Environmental Action Plan Activities and Results

- Building Low-Carbon Societies

- Building Recycling Societies

- Environmental Preservation and Building Environmentally-Friendly Societies

- Environmental Management

- Environmental Efforts at Affiliated Companies

- Environmental Data

- Third-Party Verification

- Third-Party Assessment