Building a decarbonized society

In addition to lighter weight products that lead to improved vehicle fuel efficiency, we are reducing CO2 emissions through improved productivity and more efficient distribution.

Basic philosophy

In addition to achieving the goal set under the Paris Agreement of keeping the rise in the global average temperature to below 2℃ compared with pre-Industrial Revolution levels, we believe that we must reduce greenhouse gas emissions to virtually zero by the end of this century. With the aim of minimizing CO2 emissions as presented in the TG 2050 Environmental Challenge, we are utilizing new production techniques and product development skills with an eye toward next-generation vehicles in addition to the manufacturing skills we have cultivated over time. Plans for execution are included in our 6th Environmental Action Plan with activity targets for FY2020. We have also set the goal of cutting CO2 emissions 43% by FY2030, the midpoint for the TG 2050 Environmental Challenge, and implementing stepwise, specific CO2 reductions. To reduce CO2 emissions over the entire product lifecycle, we are making efforts to increase efficiency in distribution and other areas.

Reducing CO2 emissions

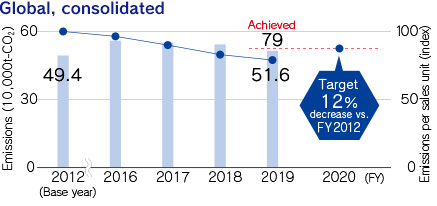

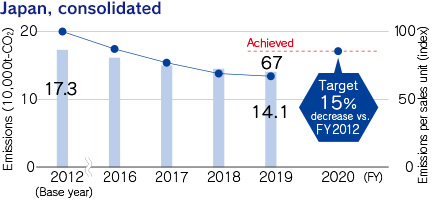

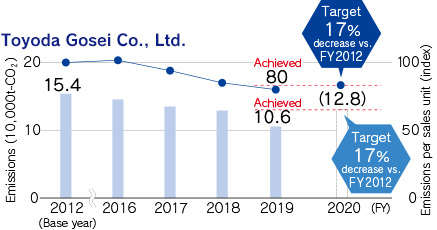

The Toyoda Gosei Group is reducing CO2 emissions (per unit sales) in the product stage, production stage, and over the entire lifecycle to achieve the targets set for FY2020.

Product development stage: Environmentally-friendly product development

In the product stage, we are making headway in providing parts for environmentally-friendly, next-generation vehicles and developing products with lighter weight for greater fuel efficiency and lower energy consumption across the areas of materials technology, product design, and production technology. Examples include aggressive efforts to switch materials (e.g., from metal or rubber to plastic) in instrument panel peripherals and other interior products and in functional parts such as hoses, reduce the number of components, integrate functions, and use thinner material while ensuring strength.

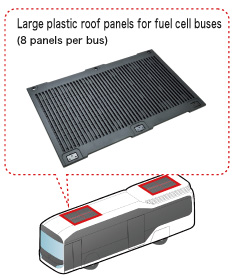

Large plastic roof panels for fuel cell buses

We have succeeded in switching from metal to plastic for lighter weight in the large roof panels placed over fuel cell stacks and high pressure hydrogen tanks. It used to be that metal had superior strength, but we have developed plastic material that contributes to lighter weight with reduced thickness while maintaining impact and heat resistance levels. We have also been able to reduce the weight of large parts with no loss of function, by using technology that forms the products with uniform thickness and high accuracy. We intend to expand this to similar products in the future.

Production stage: Reductions with development of new processes, daily kaizen

In the production stage, we are developing new production techniques that minimize energy usage and introducing energy-saving equipment through the Production Engineering Technology Environment Subcommittee started in FY2016.

We also conduct regular kaizen to thoroughly eliminate waste. Today, the TG ESCO (expert team that conducts reduction activities with genchi-genbutsu) formed in 2016 is conducting kaizen activities that include the latest technologies and collecting and applying information on best practices from other companies.

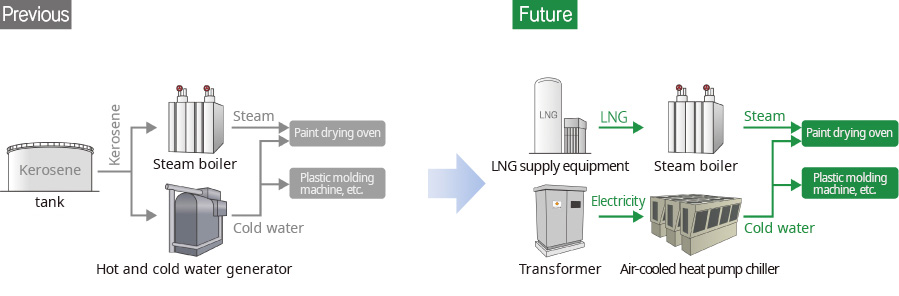

Switching fuel for boilers and hot and cold water generators from kerosene to LNG and heat pumps

Carbon emissions at the Seto Plant have been decreased by installing liquefied natural gas (LNG) equipment and switching fuel for boilers and hot and cold water generators to LNG and heat pumps. In addition to huge reductions in CO2 emissions by changing from kerosene to LNG and heat pumps to power heating and cooling equipment, this has also led to decreases in sulfur oxides (SOx) and nitrogen oxides (NOx), which are causes of air pollution.

CO2 emissions, CO2 emissions per sales unit (index)*1

- *1 Emissions per sales unit (index) is a figure obtained taking FY2012 as 100

- [CO2 conversion factor]

The CO2 conversion factors used for Japan*2 are the 1990 Keidanren factors. The CO2 conversion factors used for other countries are from the GHG Protocol (2001). - *2 Electricity: 0.3707t-CO2/MWh, class A fuel oil: 2.69577t-CO2/kL,

LPG: 3.00397t-CO2/t, Town gas: 2.15701t-CO2/1,000 Nm3,

Kerosene: 2.53155t-CO2/kL, LNG: 2.68682t-CO2/t,

Gasoline: 2.36063t-CO2/kL (excluding external factors of gas companies’ town gas heat conversion)

Recycling: Reductions in materials and parts procurement, more efficient distribution

Toyoda Gosei has prepared and distributed green procurement guidelines for materials and parts procurement with low environmental impact. Together with regular supplier surveys to ensure compliance, we also provide support when improvements are needed.

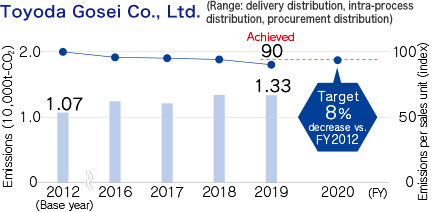

We are also making active efforts to reduce CO2 emissions over the lifecycle with more efficient distribution, including reviews of truck allocation and transport modes with the aim of improving truck payloads and shortening distribution lines.

■CO2 emissions in distribution, CO2 emissions per sales unit (index)*1

Renewable energy

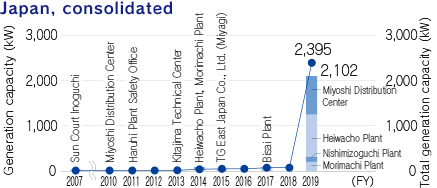

We are moving toward a target of using renewable energy equivalent to 2% of our total global electricity consumption by FY2020. This includes installation of solar and wind clean energy generation equipment and the purchase of green power. Our next challenge is to raise clean energy levels to at least 20% globally by FY2030.

■Solar power generation graph (does not include stand-alone systems such as outside lights with solar panels)

Solar power generation system installed at TGRT

A solar power system with a generation capacity of 915kW was installed at TGRT in Thailand. This is equivalent to 8% of the electricity purchased by TGRT, and has the effect of reducing CO2 by 760 tons annually.

Wind power system and geothermal air conditioning system at the Inabe Plant

The Inabe Plant has installed a wind power generation system (10kW) and geothermal air conditioning system. We are also planning to install solar power generation and other equipment.

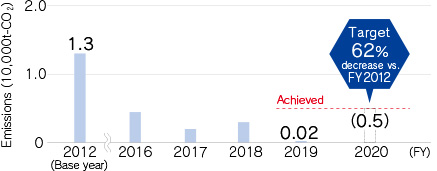

Reductions in 6 greenhouse gases*3

Of the six greenhouse gases, Toyoda Gosei Co., Ltd. uses three (HFC, PFC, SF6) and is conducting activities to reduce all of them. By FY2015 we had completed a switch to alternative gases with a low environmental impact for the shield gas used in the production of steering wheel cores and other gases. This has resulted in a 74% decrease in greenhouse gases since FY2012. We will continue these reduction activities in the future.

- *3 Hydrofluorocarbon (HFC), perfluorocarbon (PFC), sulfur hexafluoride (SF6), methane (CH4), nitrous oxide (N2O), nitrogen trifluoride (NF3)

■Trend in greenhouse gas (6 gases) emissions (CO2 equivalents)

Contributions as a pioneer in environmentally-friendly LEDs

Development and spread of products that use LEDs

Toyoda Gosei is making progress in improving the quality of light, from light that is merely visible to light that brings out the charm of things, with the development of sunlight LEDs that approach a color tone close to that of sunlight and other developments to show objects including human skin and commercial products at their most natural and appealing. To make our attractive LED technology and products more widely known, we participate in domestic and international exhibitions and events and are working to encourage the spread of LEDs.

Development of air conditioner register with LED lighting

Development of air conditioner register with LED lighting

We have developed an air conditioner register with LED lighting incorporated into the knob that adjusts the direction and strength of air flow. This improves the nighttime visibility of the knob. Wireless power transfer technology*4 is also applied to avoid previous concerns such as wire harness breakage from repeated manipulations of the knob. Together with improved nighttime manipulability, the LED register also contributes to a futuristic and elegant interior mood, while use of an LED light source helps to reduce energy consumption.

- *4 Using the physical phenomenon of resonance, in which a vibrating system drives another system to oscillate at specific frequencies, the technology enables the transfer of electric power to a distant location by causing resonance in the frequency of the magnetic fields among resonant circuits.

- Contributing to Environmental Preservation Through All Our Business Activities

- Sixth Environmental Action Plan Activities and Results

- Building a decarbonized society

- Building Recycling Societies

- Environmental Preservation and Building Environmentally-Friendly Societies

- Environmental Management

- Environmental Efforts at Affiliated Companies

- Environmental Data

- Third-Party Verification

- TCFD Index

- Third-Party Assessment