Respond to the transformation of automobiles

- HOME

- Areas of focus

- Respond to the transformation of automobiles

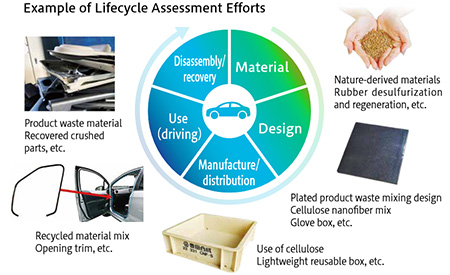

A major shift toward electrification is taking place in the automobile industry, and we are developing new Example of Lifecycle Assessment Efforts products by bringing together the polymer material technologies we have cultivated in multiple business fields and our technical capabilities in product design and production based on these technologies. In developing products for battery electric vehicles (BEVs), we seek to create new value ahead of needs, while expanding the scope of our efforts to all of CASE and contributing to the creation of safe, secure, and comfortable vehicles.

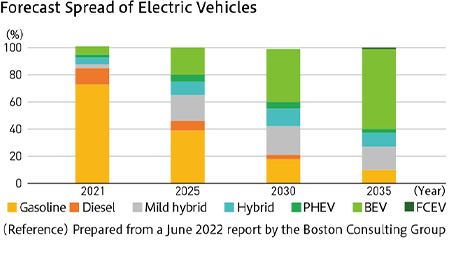

01BEV Trends

A joint statement was issued at COP26 in 2021 with the aim of making all new cars sold in major markets zero-emission vehicles by 2035, and all new cars sold worldwide zero-emission by 2040. A proposal by the European Commission in 2021 to ban the sale of internal combustion engine vehicles in the EU by 2035 was passed in June 2022, a move that further accelerates the shift to BEVs by automakers worldwide.

02Toyoda Gosei's BEV Initiatives

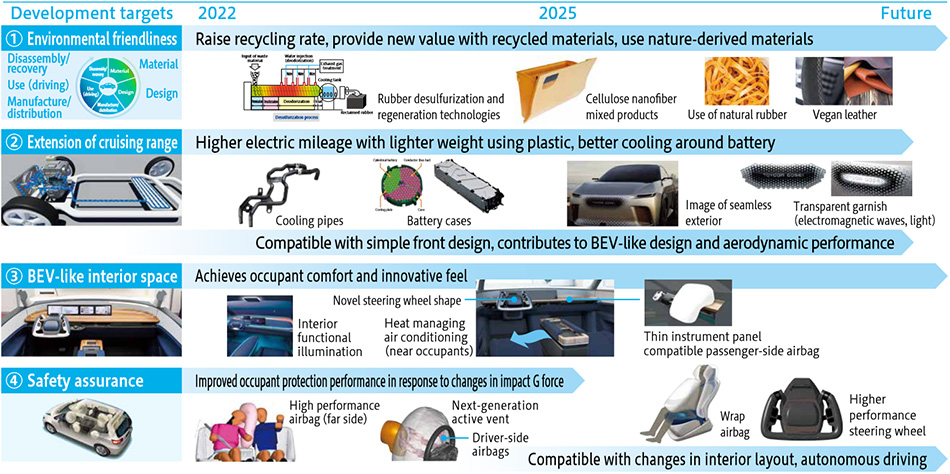

The biggest challenge for the widespread adoption of BEVs is to extend their cruising range. Environmental friendliness and user safety and comfort in response to changes in vehicle structure are also important. Toyoda Gosei's technological potential lies in its plastic and rubber material technologies and its product technologies in each business area. We believe that we can increase our potential for providing value with technologies that span multiple fields in response to the changes in vehicles and needs associated with the shift to BEVs.

We have established the following four development targets based on Toyoda Gosei's business areas, and, viewing change as an opportunity, are promoting product development while optimizing resources to quickly respond to changes in the business environment.

03Four Development Targets

-

①Environmental Friendliness

Since BEVs have a higher environmental impact than gasoline-powered vehicles during the manufacturing stage, it is important to make life cycle assessments. As a manufacturer specializing in the polymer field, we aim to provide environmentally friendly products by improving their recyclability, expanding the application in our products of rubber regeneration technology, and developing the use of naturally derived materials. Products containing cellulose nanofibers are expected to reduce CO2 emissions through both weight reduction and recyclability. We are also working on the practical application of natural rubber and vegan leather. Furthermore, we are striving to impart new value by using recycled materials, for example by using waste materials from plated products to achieve new surface designs.

-

②Extension of Cruising Range

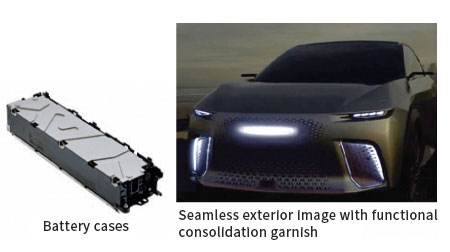

Toyoda Gosei is contributing to extended BEV cruising ranges mainly through heat management, weight reduction and aerodynamic design. We have brought together engineers from our functional component business to develop cooling systems (for example, piping and battery cases) that extract greater battery efficiency.

We utilize our materials technologies to replace metal with plastic, to make plastic and rubber products thinner by improving the material strength, and to make products lighter using our foam production engineering. In the exterior product field, seamless design with no openings is needed to improve aerodynamic performance. To achieve this design, we are differentiating our exterior products by enhancing their functionality, including decorative technologies that allow radio waves and light to pass through.

-

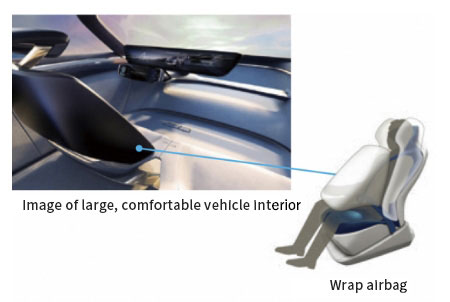

③BEV-like Interior Space

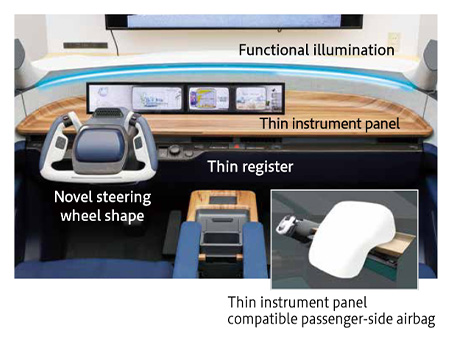

The design trend for BEV interior spaces will be for forward-looking spaces that differ distinctly from gasoline-powered vehicles. We aim to achieve such forwardlooking vehicle interior spaces through a combination of our strengths in interiors and safety systems. For example, we are developing airbags and registers that contribute to smart, thin instrument panels, and functional illumination such as driver notifications that use the entire cockpit including the steering wheel.

Our advanced steering wheels with a novel shape provide not only an ergonomic grip shape for comfortable steering, but also reflect airbag technology that ensures the same occupant restraint performance even with a steering wheel shape withvertical cutouts.

-

④Safety Assurance

The increased strength of the parts around the battery with the shift to BEVs will affect how vehicle occupants are impacted during collisions. This will require better protection performance from the restraint system. Toyoda Gosei ensures safety with high-performance airbags and internal pressure control technology. We are also developing systems together with Tokai Rika Co., Ltd. and Ashimori Industry Co., Ltd. to achieve optimal protection performance for each vehicle model through the combination of airbags and seatbelts. In addition, we are developing wrap around airbags that are integrated with seatbelts to ensure safety in response to future changes in cabin layout and occupant posture. Toyoda Gosei will continue to provide safety and security to all while adapting to various vehicle changes in the future, with the ultimate aim of zero fatalities in traffic accidents.