Customer Relations

With priorities on customers and quality, we are working to constantly improve our products and services and our value as a company.

Uniform Global Quality Assurance

Enhancing Corporate Structure through TQM*1 Initiatives

Based on the basic principles of TQM, we are implementing TQM initiatives throughout the company to enhance product and work quality and human and organizational vitality to create a flexible and strong corporate structure. In addition to traditional improvement initiatives such as the Workplace Management Improvement Initiative and Small Group Initiatives, we have established and are developing a new TQM philosophy based on the concept of anticipating change and changing how we do work.

Through TQM initiatives, we aim to create a workplace where employees can discuss anything with each other, and we are working to foster a value creation mindset in addition to a quality mindset while enhancing psychological safety.

- *1 Total Quality Management

■TQM Activities at Toyoda Gosei

| Level | Activities |

|---|---|

| Manager | Workplace management kaizen activities |

| Office, technical workers | Small group activities (group kaizen activities) Activities to improve practical abilities in statistical quality control (SQC) and machine learning (ML) |

| Skilled workers | Small group activities (QC Circle activities) |

Establishment of a Quality Assurance System and Human Resource Development That Can Respond to Future Business and Environmental Changes

Quality Assurance System Adapted to New Technologies and Newly Developed Products

We have obtained ISO 9001/IATF 16949 certification for our quality assurance system and have established a quality management system. We are also building quality into new products using an Initial Management System that checks the degree of completion of each process from planning to design to production. We are continuously working to improve the Initial Management System to ensure quality that meets customer expectations for new technologies, newly developed products, software, and experienceoriented businesses that are changing due to CASE, MaaS, and other factors.

Start of “Value Creation Community Initiative” to develop a culture of reform and innovation

Based on the new TQM philosophy of “implementing challenging reforms and innovations,” the TQM Promotion Division and New Value Creation Division collaborated in starting a “Value Creation Community Initiative” from November

Objectives of community

・Develop relationships with colleagues in other workplaces who can share a value creation mindset

・Provide a place of belonging for value creation

・Develop a culture of making changes, changing oneself, and taking on challenges without fear of failure

Establishing a Quality Mindset of Customer First and Quality First

The president’s Declaration of Global Quality Improvement, the Declaration of Thought and Action for each employee’s position and job, and the Global Quality Month in November are all part of our efforts to establish a Customer First and Quality First mindset among all Group members, including suppliers and overseas bases, through periodic review of their own actions.

We have also established a Quality Learning Center where each and every one of our employees can learn about the concepts and attitudes that should be valued in manufacturing, and where they can constantly learn about quality, from its origins to future initiatives.

Tour of the Quality Learning Center

Tour of the Quality Learning Center

Ensuring Manufacturing Quality and Continuous Improvement Initiatives

Creation of Self-Contained Processes in the Safety Parts Process

In order to deliver safe and reliable products to our customers around the world, we are working toward self-contained processes*3, particularly in the production process of safety parts, which are directly related to the basic performance (driving, turning, stopping) and safety of vehicles.

- *3 Under the philosophy of “Quality is built into the process,” we will not produce or pass on defective products.

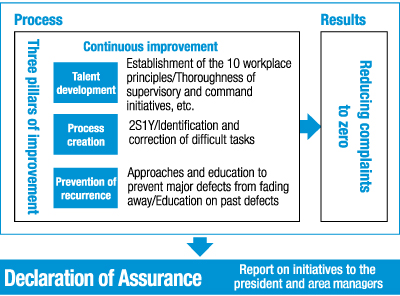

Ongoing Quality Assurance Declaration Initiatives

We are conducting Quality Assurance Declaration Initiatives with the aim of cultivating a workplace culture that enables continuous improvement and creating manufacturing sites that are resilient to change. In these initiatives, all employees participate in improvement initiatives from the perspectives of developing human resources, developing processes, and preventing recurrences, and when targets are achieved, the section manager issues a declaration of assurance to the president and area managers. The entire Group is working together to implement these initiatives, aiming for quality that earns the trust of customers globally.

(left: Japan, right: North America)

Sales Activities Aligned With Customer Needs

Toyoda Gosei sales and other departments meet the demands of customers around the world, growing sales while building good customer relationships. We collect and analyze data on customers’ needs and the issues they are facing, and then work with engineering and other relevant departments in the company to present development plans aligned with those needs to provide products that will satisfy them.