Growing together through activities with

all stakeholders

With our management philosophy of conducting business with integrity, we are committed to contributing to society through manufacturing, and are working to develop our personnel and create comfortable work environments as the foundation for such activities. Respect for human rights is also important, and is the basis for various activities with our domestic and overseas Group companies and business partners.

Employee Relations

Revitalization of People and Organizations

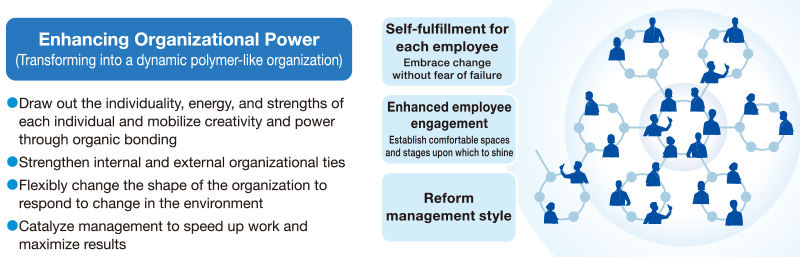

Corporate Culture and Human Resources to Support Achieving of the 2030 Business Plan

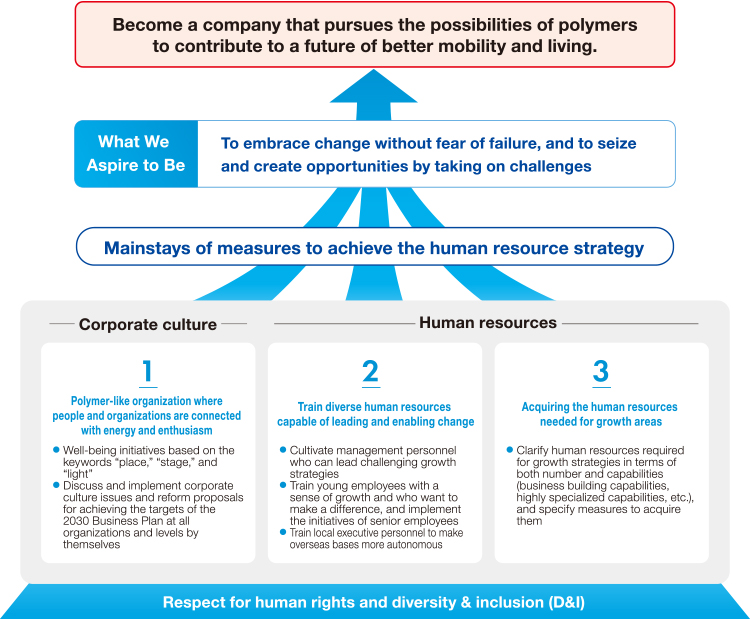

In order to achieve the targets in the 2030 Business Plan, we believe it is important to embrace change without fear of failure, and to seize and create opportunities by taking on challenges, and we will develop measures for enhancing both corporate culture and human resources.

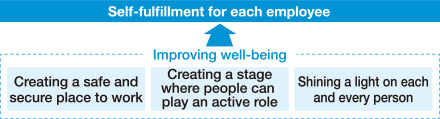

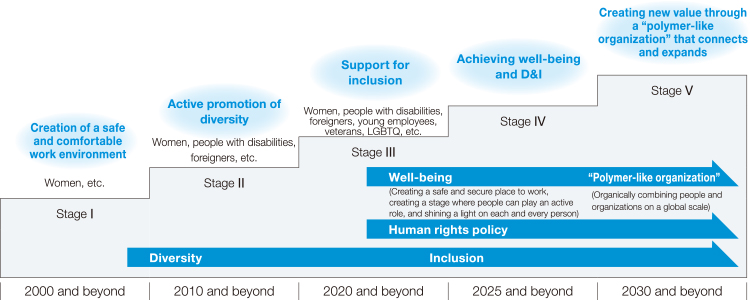

In terms of the corporate culture, we aim to create a dynamic “polymer-like organization.” Each and every molecule with various personalities and values stimulates each other, enhances creativity by creating chemical reactions, and brings together power through strong bonds among molecules. The same stimulation and reaction occurs among teams, groups, divisions, and affiliated companies, as well as with other organizations such as partner companies, suppliers, business partners, and customers, resulting in a high level of creativity and productivity. We are able to freely change our form and create new value in response to changes in the environment. This is what we think of as a polymer-like organization. In order to create the corporate culture that is a foundation for this, we will support the attainment of employee wellbeing through Self-realization by creating a safe and secure place to work, creating a stage where they can play an active role, and shining a light on each and every one of them.

In the area of human resources, on the other hand, TG aims to develop human resources who can ask themselves questions about the social value and significance of TG’s existence and strategically develop their businesses. To this end, we are working to acquire diverse human resources and review our business portfolio.

Toyoda Gosei’s goals for employee wellbeing

Creating a safe and secure place to work

Diverse human resources can recognize each other and speak up and take on challenges in a safe and comfortable environment. Vitality and trust exist in the workplace, and people are motivated to do their best work with other members.

Creating a stage where people can play an active role

Employees can feel that they are contributing and feel that they are truly making a difference in their roles.

They understand the significance of their work and feel job satisfaction.

Shining a light on each and every person

Employees are recognized, encouraged, and praised.

Regardless of the size of their role, their supervisors look out for them and treat them with the respect.

Our Human Resources Strategy Linked to Our Vision and Business Plan

We regard the use of diverse human resources and respect for human rights as one of our materiality (key issues), and have been focusing on the three pillars of our human resource strategy: promotion of human resource development, active participation of diverse human resources, and creation of a comfortable work environment, and have been working to provide educational opportunities to acquire problem solving methods and the PDCA cycle, which are fundamental to how work is conducted, as well as specialized knowledge in areas such as technology and materials, to create an environment where women, people with disabilities, and people with diverse values can demonstrate their abilities, and to improve engagement, where job satisfaction and a sense of growth overlap with our efforts to achieve our corporate vision.

However, when examined in light of human capital management, which today is expected to be a significant method for increasing corporate value, our human resource strategy to date has been based on the recognition of issues from the perspective of human resource functionality, and so we have revised our human resource strategy (see figure below). In FY2023, we will further strengthen the linkage with the management strategy, and based on the newly formulated strategy, we are developing new measures and implementing new initiatives in addition to the previous ones.

■Key KPIs

Employee engagement

affirmation rate

75% (FY2030)

Number of expatriate

employees for training

50 (FY2030)

Ratio of local executives

60% (FY2030)

Number of female managers

100 (FY2030)

Respect for Human Rights

Basic Philosophy

The Toyoda Gosei Group (Toyoda Gosei Co., Ltd., and domestic and overseas affiliates) respects and supports the United Nations’ Universal Declaration of Human Rights, the UN Guiding Principles on Business and Human Rights, and other international norms. The Toyoda Gosei Group Charter for Business Ethics lays out our basic principles of “respecting human rights and the diversity, character, and individuality of each person and striving to create workplaces that are free of discrimination and harassment and always healthy, pleasant and safe, based on labor-management cooperation.” The Toyoda Gosei Guidelines for Business Ethics, our behavioral standards to realize the ideals in the Charter, declares respect for individual character, human rights, and fairness in hiring, and forbids forced labor and child labor.

■Toyoda Gosei Group Human Rights Policy

In order to accelerate existing efforts to Respect Human Rights activities, we have established “Toyoda Gosei Group Human Rights Policy” in April 2022. The policy was developed with a support from external experts, reviewed by all Officers and Chiefs of Divisions at the Sustainability Meeting and approved at the Board of Directors Meeting. Also, we have shared the “Sustainability Guideline for Suppliers” with our suppliers and asked for their cooperation.

Reporting Structure

Respect for human rights activities are discussed at meetings attended by Directors, and the results of those discussions are reported at Sustainability Meetings headed by the company president.

Human Rights Due Diligence

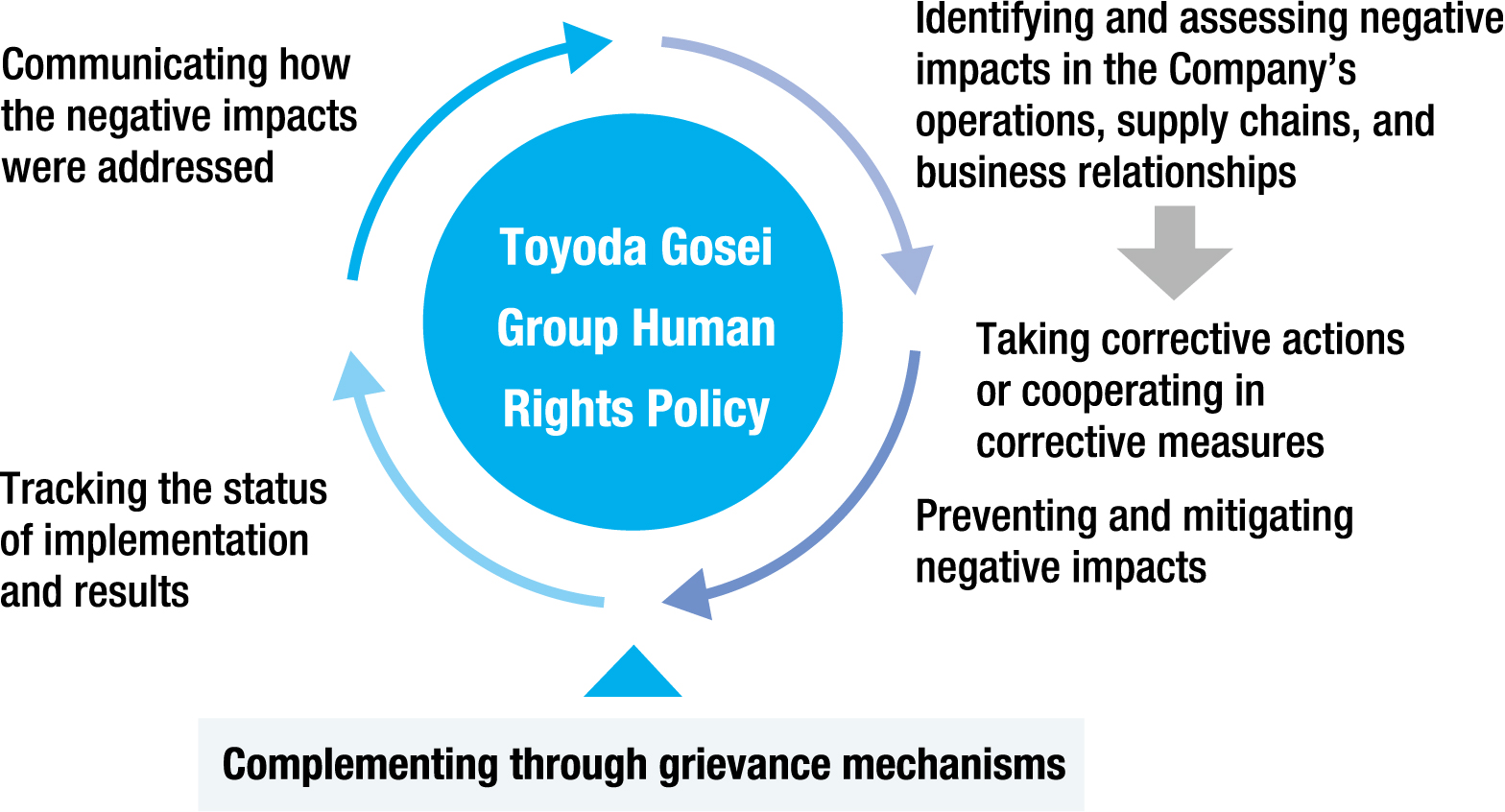

The Toyoda Gosei Group, in order to implement initiatives based on its Human Rights Policy, began human rights due diligence in accordance with the United Nations Guiding Principles on Business and Human Rights in 2022.

Human rights due diligence refers to the process of identifying adverse human rights impacts related to a company's operations, supply chain, and other business relationships, and then preventing and mitigating those negative impacts, tracking implementation and results, and communicating how those impacts have been addressed.

■Overview of Human Rights Initiatives

Human Rights Impact Assessment

As part of our human rights due diligence, we first conducted a human rights impact assessment together with external experts to identify the human rights issues within the Group that should be prioritized (salient human rights issues). Assessments of priority issues are also being conducted for domestic and international supply chains, and results will be disclosed in FY2024.

To obtain an overall picture of human rights risks associated with the Group’s business activities, products, and services, we first conducted a desktop survey to uncover human rights risks in the Group’s value chain. In addition, as a result of the survey, we conducted a questionnaire survey of Group companies, plus interviews in countries and regions with high risks, to confirm the actual status of and issues in efforts in this area. Then, based on the findings of these surveys, we evaluated and prioritized each human rights issue and identified salient human rights issues within the Group.

■Process of Human Rights Impact Assessment

-

Desktop Survey

- Comprehensively designate human rights risks specific to the Group’s business areas, products, countries/regions, and companies, utilizing indices and reports published by international organizations, governments, NGOs and others, internal documents, and the knowledge of external experts.

-

Survey & Interviews

- Survey: Conduct a web-based questionnaire survey for the entire Group to comprehensively investigate the situation of each company.

- Interview: Conduct interviews with Group companies in countries and industries found to be at high risk based on the desktop survey, and investigate their management situation and past cases.

-

Prioritization/identification of salient human rights issues

- Evaluate the degree of impact on human rights based on the results of the desktop survey, online survey, and interviews.

- Based on the evaluation results, and through consultation with external experts, identify human rights issues that should be prioritized as “salient human rights issues“ for the Group after approval by management.

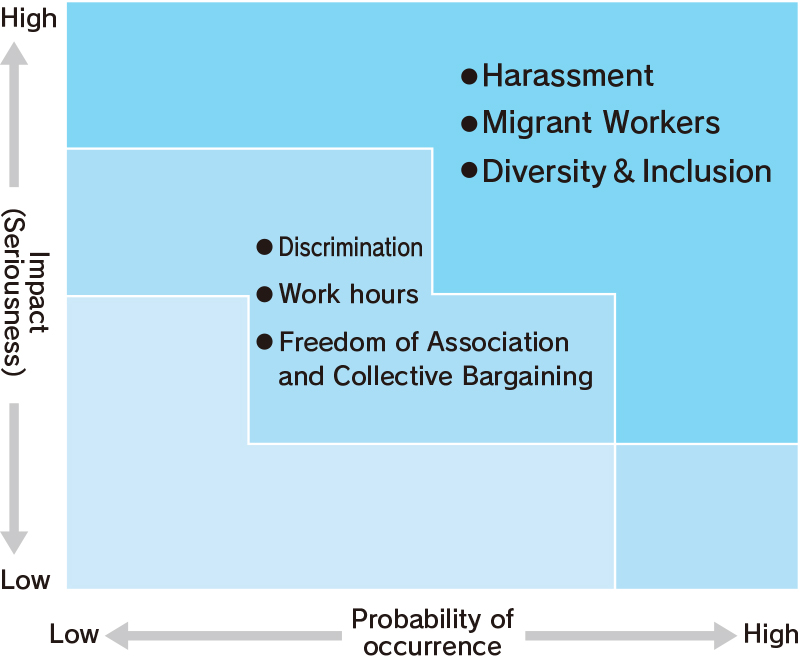

As a result of the assessment, the three issues below were identified as salient human rights issues for which Toyoda Gosei should strengthen its management structure, and which should be prioritized.

With the cooperation of related departments, we will promote initiatives to prevent and mitigate negative impacts associated with the identified salient human rights issues. In addition, since the situation surrounding human rights is constantly changing, we will continue to conduct human rights impact assessments on a regular basis.

- * NB. Although “occupational health and safety” was also raised as an important human rights issue in the evaluation process, “occupational safety and health” was excluded as a priority issue in human rights due diligence because a Group-wide management system has already been established for this and initiatives are being promoted based on the PDCA cycle.

■Salient Human Rights Issues Within the Group

| Salient issues | Impacted stakeholders | Contents |

|---|---|---|

| Harassment |

|

|

| Migrant Workers |

|

|

| Diversity & Inclusion |

|

|

■Human Rights Risk Matrix

Initiatives

■Employee education and training

Up to this time, Toyoda Gosei has provided education on respect for human rights on various occasions, such as when people join the company and when they are promoted. However, with the establishment of the Toyoda Gosei Group Human Rights Policy, the company has begun hosting presentations by outside lecturers on well-being and DEI, giving explanations of the company’s human rights policy in company newsletters, providing online training for technical and administrative staff, and developing awareness tools for skilled workers. Monthly communications are issued to create workplaces free of harassment and discrimination. Other efforts include training of representatives who will have a high sensitivity to human rights, including sending personnel managers to outside training for professional learning on human rights problems.

| Target | Content | Frequency |

|---|---|---|

| Managers | Training on basic knowledge of human rights and unconscious bias | 1 time/year |

| All employees | Basic content on human rights delivered through e-learning | 1 time/year |

| Human rights representatives | Participation in outside study sessions for basic knowledge and behavior | As needed |

| Group company managers | Training on basic knowledge of human rights and unconscious bias | 1 time/year |

■Harassment Prevention

Together with training for executives, managers, supervisors and others, a “TG Positive Workplace Support Squad” report is sent out about once a month and all employees strive to create a healthy and pleasant workplace free of harassment. In particular, ongoing training is provided to all people in supervisory and above positions to decrease harassment.

■Foreign technical interns

In 2023, a written survey was conducted on the employment situation at domestic Group companies, and it was confirmed that a total of 78 trainees had been accepted at six companies (as of July 2023). Each of these companies was asked to conduct a voluntary inspection of the workplace environment, health and safety, and document management similar to the inspections issued by the Japan International Trainee & Skilled Worker Cooperation Organization (JITCO). All group companies were then visited and on-site surveys were conducted, including trainee interviews and workplace tours. Toyoda Gosei provides guidance and implements immediate corrective measures for any shortcomings identified to ensure that there are no violations that could lead to human rights abuses. In these surveys, it was learned that more than half of trainees come from Vietnam, and efforts are also being made to ensure that fees charged are appropriate.

■Efforts at Domestic and International Group Companies

Self-check surveys are conducted at 61 Group companies (as of April 2023) in Japan and other countries to understand the status of human resources management compliance and human rights in accordance with the laws of each country and the Toyoda Gosei Group Charter for Business Ethics. Regular study sessions related to human rights, harassment, and diversity and inclusion are held within the Group to share knowledge that leads to improvement activities at each company. Head office employees also visit Group companies to provide training on site.

■Efforts for the respect of human rights in the supply chain

Toyoda Gosei also seeks to ensure that suppliers do not violate human rights or contribute to human rights abuses. The company’s Supplier Sustainability Guidelines includes necessary items for the respect of human rights, such as prohibitions on forced labor and discrimination. Suppliers are asked to understand and implement these guidelines. Toyoda Gosei provides suppliers with check sheets for the purpose of becoming aware of hidden risks and taking early corrective measures, and has suppliers conduct self-inspections.

Regular human rights awareness activities are conducted through supplier liaison meetings and other channels.

Toyoda Gosei will continue efforts in coordination with suppliers to prevent and mitigate negative impacts.

■Grievance mechanisms

Toyoda Gosei has established internal and external channels that are available to employees of both Toyoda Gosei itself and Group companies. People can seek advice and make reports anonymously, and efforts are being made to protect the people who use these channels so that they will not be treated unfairly as a result of coming forward with concerns or reports.

An internal consultation service has also been established for matters including harassment, child and nursing care, and employment support for people with disabilities, and the company is striving to create an environment where employees can work in mutual respect.

A supplier consultation service has also been established for inquiries and reports from suppliers, while all stakeholders can consult or make reports through the “Contact us” section on the company’s website.

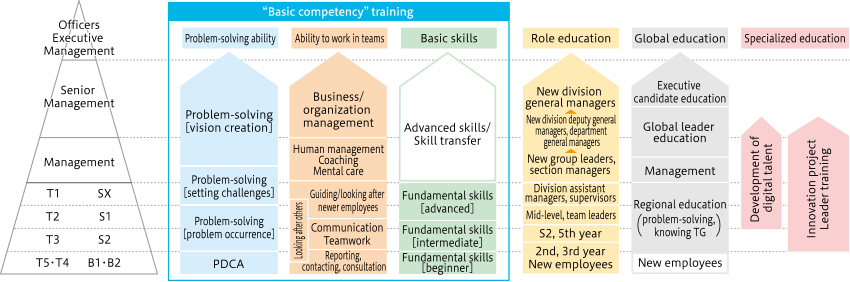

Promotion of Human Resources Development

To raise the collective strength of Toyoda Gosei globally, we are striving to develop human resources and create workplace environments where everyone can display their full abilities.

Enhanced Training Programs, Invigorated Personnel Development

To improve the skills and abilities needed in working at Toyoda Gosei, we are encouraging human resources development in three key areas: problem-solving, which is fundamental to work; the ability to work in teams based on communication; and basic skills for strong on-site abilities.

We have also launched a new training program to develop project leaders who can bring about reforms in order to respond to changes in the business environment, and digital talent to promote DX. We are also actively introducing online training, e-learning and other new training methods.

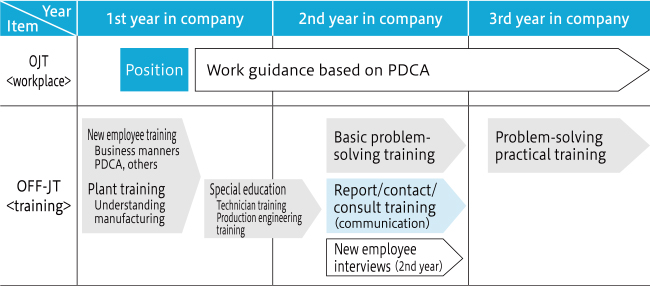

■Level-Specific Education System

New Employee OJT System

For early employee education, we have introduced a “New employee OJT system” for independence of young employees within three years of joining the company. We provide both on-the-job training and classroom training in the workplace so that they can perform their work according to the PDCA cycle.

Interviews in the pivotal second, fourth and sixth years in the company help them display their abilities, understand their individual growth, discover educational problems early, and take measures to counter them.

Special Skills Dojos, Maintenance Skills Dojos, and Mold Skills Dojos Raise the Level of Skill on the Manufacturing Floor

Improving the skills of each worker is an indispensable part of enhancing manufacturing capabilities at production sites. We therefore started up three dojos in FY2019 with the basic policy of “cultivating a culture that values skills.”

The Special Skills Dojo is designed to help managers and supervisors acquire specialized skills in addition to their supervisory duties. We have started a training program where they learn the mechanisms that lead to defects so that they are better able to take corrective actions.

In the Maintenance Skills Dojo launched to train maintenance personnel, we have added application-level training to respond to the shift to robotics and IT. To promote autonomation through the use of collaborative robots on manufacturing floors, general shop floor workers are also being trained in robot teaching skills. In FY2022, we have also begun to create a curriculum to train people who will bring autonomation to existing processes through the use of collaborative robots.

The Mold Skills Dojo provides basic skills training and trainer training for mold maintenance personnel at domestic and overseas locations. So far a total of 100 people have been through this dojo.

We have been entering the Skills Olympics since 2017. By helping young employees to acquire the high-level skills and knowledge related to their essential work, we are striving to develop employees who can play active roles on the production floor in the future. With these ongoing initiatives, we hope to achieve strong manufacturing floors that support the company.

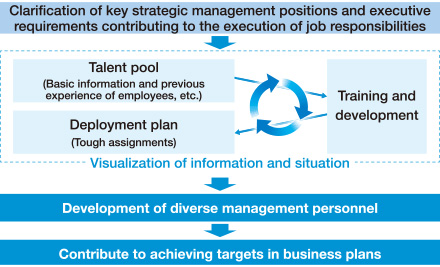

Acquiring and Developing Candidates for Management Leadership

To systematically develop human resources who can assume roles in future management, we have adopted a comprehensive system from management strategy to personnel selection, training, and assignment. We acquire future executive candidates for important posts in each generation, starting with young employees, and continuously develop them through training and putting their training into practice (tough assignments). We will develop diverse human resources who can lead and realize change by appointing local staff/employees from outside the company.

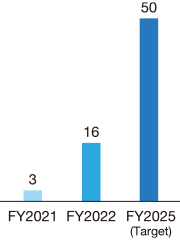

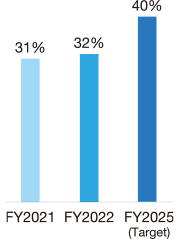

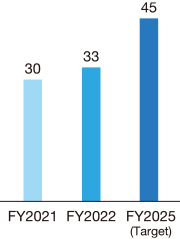

Local Executive Training

With 62 companies in 16 countries and regions around the world, we aim to achieve operations rooted in the local communities that support sustainable growth. For such business operations, we believe the involvement of personnel who are familiar with local business practices and culture is essential, and we are actively appointing and training local executives at our overseas locations. To accelerate the active promotion to such positions in each region, we established a basic policy and targets for the promotion of local executives (vice presidents and above) in FY2021, and each business unit is working to achieve these targets.

With the aim of having 40% local executives by 2025, we are evaluating people with high potential in each region and formulating plans for their development. We are also developing local human resources by providing basic management skills training and problem-solving training for executive candidates. In addition, Regional Succession Committee (RSC) meetings are held in the Americas, Southeast Asia, and China to share the status of activities and issues related to the development and recruitment of successor candidates for executives. Reports are given at Global Succession Committee (GSC) meetings held annually at the headquarters.

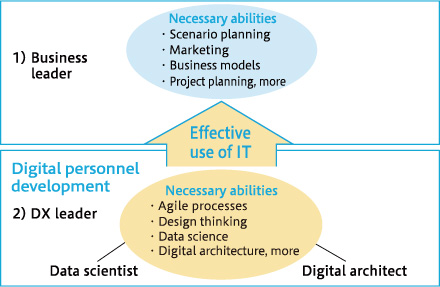

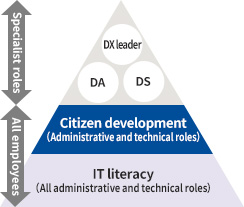

Project Leader Training in the Age of VUCA

In addition to training based on problem solving, we believe people need to develop the expertise, capabilities, and skills required to respond to changes in the business environment and implement management strategies. We have started a training program where people learn new ideas, approaches, and other skills to create new value and take the lead in innovating business operations. Three types of project leaders are trained: 1) Business leaders who create new businesses and products, 2) Business innovation leaders who innovate business processes, and 3) DX leaders who lead digital human resources and promote DX. This training has been fully implemented since September 2022.

Digital Personnel Development for People Who Can Carry Out DX

In response to the rapidly changing business environment, we are overhauling production processes and products using data and digital technology. While transforming our business model, we are also transforming the work itself and the organization, processes, corporate culture and atmosphere. We will continue this DX to gain a competitive advantage. Training people who can do this is an urgent task, and in January 2022 we introduced a new educational program to train core digital personnel.

With this we will ensure business innovations and our competitiveness in the market, so that we can grow as an organization that can respond flexibly and rapidly to market changes.

■Digital Personnel Education System

| Necessary DX personnel | FY2021 results | FY2022 results | Training plan for 2025 (cumulative) |

|

|---|---|---|---|---|

| Data scientist | Can extract and analyze information from large amounts of data and reflect it back to work improvements | 57 | 72* | 150 |

| Digital architect | Is well-versed in the latest cloud and other technologies, and can implement them | 24 | 30* | 100 |

| DX leader | Can direct digital talent and promote DX | - | 7 | 20 |

- * including affiliate companies

Workplaces That Welcome People with Disabilities

We view the hiring of people with disabilities as a social responsibility, and make active efforts in this area. The Committee for Employment of People with Disabilities implements hiring, job assignments, manager and supervisor education, and workplace settlement. We place particular emphasis on getting people settled in the workplace, monitoring conditions through regular care interviews, taking up problems, and formulating 3-year plans for improvement of the workplace environment. We are also systematically installing restrooms for all with consideration of the workplace environment. Work that people with disabilities can perform is identified, and they are systematically hired and placed. As of the end of FY2023 (May 1, 2023), 127 people with disabilities had been hired for a hiring rate of 2.4%, exceeding the legally mandated employment rate of 2.3%.

Our special subsidiary TG Welfare Co., Ltd. holds seminars for people with disabilities for the entire Group and serves in other ways to create places for education and share information with 14 Group companies that have received special Group company certification, achieving a hiring rate of 2.8% for the Group overall.

■Employment Rate of People With Disabilities

Mid-career hires

Toyoda Gosei hires people mid-career in order to bring in know-how and knowledge not available in the company. Approximately 30% of company employees are hired mid-career, and the company is creating a workplace environment where these employees can play active roles, providing them with introductory training after they join the company and education in each workplace. These employees are also interviewed by human resources staff with regard to any problems or difficulties they may have.

Continuing Roles of Senior Employees

We will create an environment in which senior employees, who are steadily increasing in number, can continue to work with a sense of security and high motivation after the age of 60. This will create new value by combining their wealth of experience, techniques, and skills with the ideas and perspectives of younger employees. To build a foundation for this, we have raised the retirement age from 60 to 65, effective April 2022. We will continue the initiatives shown in the table on the right to encourage employees to continue working enthusiastically and vigorously until age 65.

We are continuing activities to create an environment in which employees, regardless of age, can maximize their potential and to further improve engagement (target: positive response rate of 65% or higher for employee engagement (50s and 60s)).

For example, as a means of improving motivation, we conduct career training for employees in their 50s, providing them with opportunities to exchange opinions with their peers and rethink such matters as how they will work in the future and how to demonstrate the techniques, skills, and experience they have cultivated in the workplace.

In addition, to improve health and physical fitness, we are stepping up activities to promote health through regular discussions with employees, such as holding health seminars at milestone ages and reviewing cafeteria menus to improve dietary habits.

| Increasing motivation |

|

|---|---|

| Health and physical fitness improvement |

|

| Workplace environment improvement |

|

Career Development for Young Employees

In the automotive industry, which is said to be undergoing a once-in-a-century major transformation, we must enhance our corporate competitiveness for further growth and development as a company. To this end, we believe that it is essential for each and every employee to achieve their fullest potential and growth, while gaining a sense of fulfillment and satisfaction by drawing up their own career plans and achieving self-fulfillment.

Since FY2021, we have been implementing Waku-Cari Initiatives (initiatives to raise awareness of career development with excitement and high energy) and positioning the three pillars of the Waku-Cari Initiatives as priority measures as shown in the table below. In the future, we will further expand measures (career development initiatives) to help employees realize their individual career plans in cooperation with their supervisors, centering on “a safe and secure place to work” and “a stage where people can play an active role.”

| Visualization |

|

|---|---|

| Developing awareness |

|

| Career development initiatives |

|

Creating a Pleasant Corporate Culture

Toyoda Gosei believes that the development of various systems and measures to improve job satisfaction are crucial for employees to work with energy and enthusiasm. The company provides a safe and comfortable work environment and is actively creating a foundation for each individual to demonstrate their fullest abilities.

Initiatives to Improve Well-Being

We have always been committed to creating a pleasant corporate culture, and in response to the 2030 Business Plan, in order to take full advantage of these initiatives, we have been working to create an environment and systems that enable each employee to achieve self-fulfillment, placing importance on efforts to revitalize people and organizations. To achieve this goal, we are implementing measures to enhance well-being and to enable horizontal collaboration.

Measures to enhance well-being are centered on the three pillars of “Creating a safe and secure place to work,” “Creating a stage where people can play an active role,” and “Shining a light on each and every person.” In FY2023, we have been working on “Creating a workplace where people can communicate with each other” with the aim of changing the management style to one where managers are close to their employees and make the most of each individual’s values. Training is provided to management-level employees (GLs and section managers), and by having them put their training content into practice, we aim to build relationships of trust and bonding.

LGBTQ Initiatives

Toyoda Gosei has revised some of its systems, effective April 2023. This includes granting employees with same-sex partners special marriage or bereavement leave under the same rules as for those who are legally married. The company has also installed gender neutral restrooms and set up consultation services with sensitivity to diverse sexuality, and established in-house awareness training. In recognition of these efforts, the company received the silver award in the “PRIDE Index 2023,” an evaluation index for LGBTQ+ and other sexual minorities in the workplace in Japan, developed by the Work with Pride foundation.

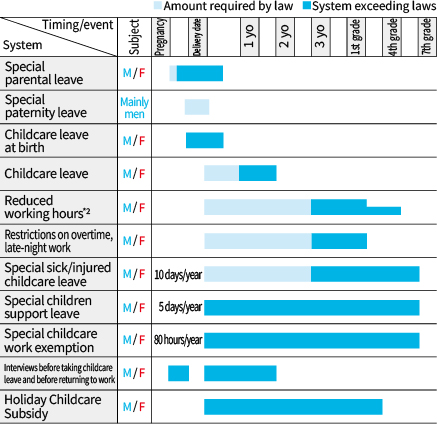

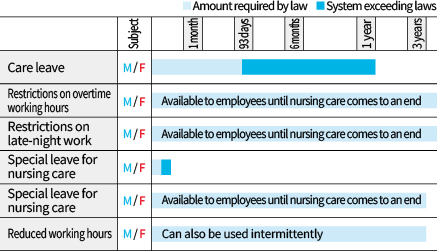

Creating Systems and Environments for Flexible Working Styles and That Support Increased Activity

In addition to systems that exceed the legal requirements for support in balancing work with childcare, nursing care, and medical treatment, we are fostering a workplace culture of mutual consideration. In particular, as both men and women participate in childcare, we actively encourage male employees to take childcare leave by reminding them of the system when their children are born and by raising awareness through our in-house newsletters.

To help employees achieve a work-life balance, we also strive to create an environment where they can continue to work with a sense of fulfillment, using flexible work styles such as telework, shorter working hours, and flexible work schedules.

Major Systems for Childcare Support

In addition to the above, we have other generous programs such as Special Children Support Leave so that parents can attend children's events or deal with school closures and a Holiday Childcare Subsidy to subsidize the cost of using a private daycare center on holidays that are working days for the company. Other programs include a Special Childcare Work Exemption and interviews before taking childcare leave and before returning to work.

- *2 4-hour workday up to first grade of elementary school, 6/7-hour workday up to fourth grade of elementary school

Major Systems for Care Support

System to Support a Balance Between Work and Medical Care

- Reduced working hours

- Half-day work

- Relaxation of upper restrictions on telework

Company-Wide Average Overtime Hours [Toyoda Gosei Co., Ltd.]

Number of Men Who Took Childcare Leave [Toyoda Gosei Co., Ltd.]*4

- *4 No. corresponding to the year when childcare leave was started

Annual Paid Leave Taking Rate [Toyoda Gosei Co., Ltd.]

- *3 There were company shutdowns due to COVID-19

Vital and Cohesive Company Culture

Toyoda Gosei holds various companywide events to foster a sense of unity in the workplace. 2023 marked the first time in four years that the company held its all-Toyoda Gosei ekiden distance relay race with spectators. A total of 1,100 runners, from both Group companies and suppliers, participated in the event, while approximately 1,000 workplace colleagues and family members came out to cheer them on. The “TG Festival” was also held for the first time at the company’s Entrio arena to deepen family ties and interactions with the local community. In addition to these events, the Morimachi Summer Festival was held at the Morimachi Plant and Family Day was held as an occasion for employees to invite their families to the company. Through these events, ties among employees and with the community are strengthened. The events are planned as a way for the company to show hospitality and express its gratitude for the daily support, understanding, and cooperation it receives.

Safety and Health

Basic Philosophy

Basic Policy for Safety and Health

The Toyoda Gosei Group considers employee safety and mental and physical health to be one of the most important management issues, and we do our best to ensure secure and pleasant workplace environments for all business activities.

Safety and Health Initiatives

In the Toyoda Gosei Group, safety and health declarations are made and company activities are spread based on the above basic philosophy.

Safety and Health Declaration

- 1. Compliance with laws and internal regulations and standards related to health.

- 2. With “safety before all” foremost in mind, thorough safety-first behavior by all employees.

- 3. Cultivation of a culture of safety in which activities are conducted with a sense of ownership and there is mutual development with participation by all employees.

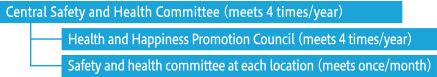

Implementation System

The Central Safety and Health Committee, chaired by the general manager in charge of the Safety & Health Promotion Division and attended by the president, the labor union chairperson, all plant managers in Japan, and the presidents of domestic and overseas subsidiaries, meets four times a year to report and deliberate on various safety and health-related measures, and report the results of these deliberations to the Board of Directors.

In addition to the deliberation results of the Central Safety and Health Committee, the entire company works together to implement initiatives by repeatedly disseminating safety information through the president’s New Year message and company newsletters. We also regularly share information with our suppliers through procurement liaison meetings and other means.

Targets and Achievements (Global)

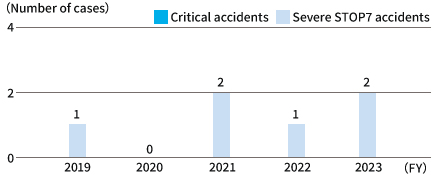

Based on the belief that it is the company’s responsibility to ensure that all employees return home from work in the same good health state as they arrived at work, we have set a global target of zero critical*4 and severe*5 STOP7*6 accidents, and are implementing various measures. In FY2022, we implemented initiatives to prevent entanglement accidents by focusing on eliminating hazardous sources, isolating hazardous sources, and shifting to inherent safety measures through automation and other means.

In FY2022, to prevent entanglement accidents in which a worker gets caught in a machine, “separation” measures were taken to remove workers from contact with sources of danger. A “shift to essential safety measures,” in which sources of danger are eliminated or their energy is reduced, has also been adopted as a priority measure in the company’s activities.

■Global Target Achievement in FY2022

| Result | Assessment | ||

|---|---|---|---|

| No. of critical accidents | 0 | 0 | ◯ |

| No. of severe STOP 7 accidents | 0 | 1 | × |

| No. of lost time injuries | 0 | 0 | ◯ |

- *4 Critical: Death

- *5 Severe: Victim loses part of body (or function)

- *6 STOP7: Seven events that may cause serious injury: (1) Crushing or entanglement, (2) Heavy object, (3) Drop or fall, (4) Electric shock, (5) Vehicle, (6) Hot object, explosion, or gas, (7) Amputation

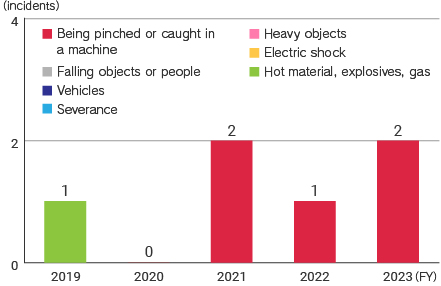

■Global Critical and Severe STOP7 Accidents

(including contractors and engineering companies)

Specific Efforts

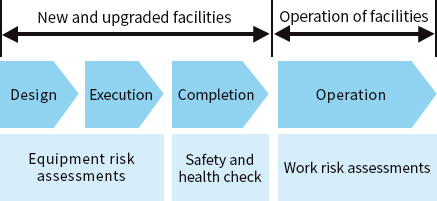

■Safety and Health Management System

Globally, we have introduced and operate labor safety and health management systems centered on risk assessments.

After obtaining OSHMS certification, Toyoda Goseihas been voluntarily operating its own system with the addition of internal control items.

- As of December 2023

| ISO 45001 certification body | OHSMS certification body | Independently operated companies/plants | |

|---|---|---|---|

| Toyoda Gosei Co., Ltd. (11 plants) | ― | ― | 11 |

| Subsidiaries in Japan (12 companies) | ― | 4 | 8 |

| Subsidiaries in other countries (31 companies) | 14 | 1 | 16 |

■Equipment risk assessments

Risk assessments of equipment are conducted at the time of new installation, modification, and relocation by equipment planning departments, with the purpose of eliminating risk factors in the equipment design and fabrication stages. A safety check is done at the stage before the equipment is used to evaluate compatibility with our own equipment safety criteria to confirm safety.

■Work risk assessments

In manufacturing departments, surveys of workplace risks and hazards are performed and work risk assessments are done to counter them. Reliable implementation of risk reduction measures leads to the prevention of risk.

■Safety and Health Education

Educational curricula are set and various educational programs are provided in line with position in the company and timing of needed training. Because of the coronavirus pandemic and other factors, Web-based education is carried out in addition to conventional in-person education.

Safety Dojos have also been set up and are being operated at all Toyoda Goseibusiness locations in Japan to prevent past accidents from fading and to teach employees to sense risks. These dojos are being spread globally.

Safety and Health Education by the Safety & Health Promotion Division and Number of Students (FY2022)

| Name of training/education | Targeted persons | Classroom education | Web-based education*8 | No. of students |

|---|---|---|---|---|

| Mid-level skilled worker training | Skilled work next-term supervisor candidates | ○ | 30 | |

| New supervisor training/TL safety & health education | Newly promoted/assigned individuals | ○ | 100 | |

| Safety and health education for new managers | Newly promoted individuals | ○ | 50 | |

| Safety and health education for senior managers and managers in manufacturing divisions | Senior managers and managers in manufacturing divisions | ○ | 9 | |

| Pre-overseas assignment training | Individuals scheduled for overseas subsidiary assignment | ○ | 98 | |

| Overseas leader, No. 2 pre-assignment training | Individuals scheduled for overseas subsidiary assignment | ○ | 5 |

- *8 Web-based education: A learning format in which two-way communication is possible on the Web

■Domestic and International Subsidiary Audits

We have been using safety and fire prevention maps (SFPM) since FY2020 for the purpose of understanding the safety and fire prevention levels at our domestic and international subsidiaries and rectifying weaknesses.

In FY2022, uniform assessment items were again established based on the results of voluntary assessments at each company. For domestic subsidiaries, on-site physical audits and support are conducted three times a year (13 companies: 39 times in total).

For 31 overseas subsidiaries, the assessment results (activity content) of each company are checked at regular Web meetings. For companies who are judged to require further improvements, Web-based guidance meetings utilizing videos and various materials are held once a month to improve safety levels.

Work Accident Occurrence

To prevent entanglement accidents in which a person gets caught in a machine, with the aim of achieving zero critical accidents and severe STOP 7 accidents globally, Toyoda Gosei has been shifting to measures that isolate people from sources of danger and measures for essential safety. Despite this, one severe STOP 7 accident corresponding to machine entanglement occurred at an overseas subsidiary.

Analysis of the causes of the accident revealed that the risk identification was weak and safety measures remained too dependent on humans. To address this, the company has incorporated initiatives aimed at establishing a culture of risk assessment globally, and continues to work towards preventing critical and severe accidents.

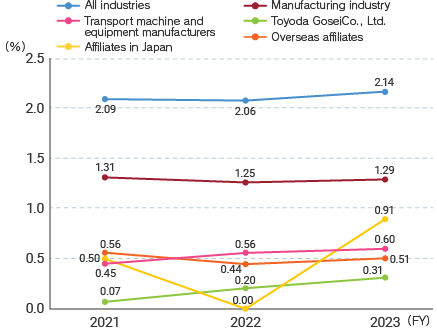

■Trends in serious STOP 7 accidents in the Toyoda Gosei Group

■Trends in the Labor Accident Rate in the TG Group

(rate of lost-worktime injuries)

■FY2022 Toyoda Gosei Co., Ltd. Safety Performance

| Item | Calculation formula, disclosure method | Toyoda Gosei Co., Ltd. | Transport machine and equipment manufacturers | Manufacturing industry |

|---|---|---|---|---|

| Fiscal year (April to March) | Year (January to December) | |||

| Time lost to industrial accidents (average no. of days of lost work per casualty) |

Average no. of days of lost work per casualty: Reference: No. of days lost |

1.0 | 64.3 | 59.9 |

| No. of industrial accidents (lost time injury frequency rate) |

Lost time injury frequency rate:

|

0.195 | 0.56 | 1.25 |

| No. of industrial accidents (total accident frequency rate) |

Total injury frequency rate:

|

1.5 | 2.69 | 3.98 |

| No. of deaths due to industrial accidents | *Includes no. of deaths from Covid-19 | 0 | 5 | 37 |

- Source: Ministry of Health, Labor and Welfare “Survey on Industrial Accidents (January–December)”

Health Management

Basic Philosophy

We conduct health management activities so that all people working in the Toyoda Gosei Group can continue working in both mental and physical health.

Health Declaration

To Achieve “Boundless Creativity and Social Contribution”

- 1. We believe the health of our employees is an important management resource and will strive to foster an organizational culture that puts safety and health first.

- 2. We will strive to create positive and lively workplaces where employees can work energetically, and develop our personnel.

- 3. To help improve the health of employees and their families, we try to raise health awareness for disease prevention.

Promotion System

With the aim of upgrading health management, the mental and physical health committees were merged to form the Health and Happiness Promotion Council in FY2022. Aiming not only for good health but also for happiness in work, industrial physicians and the company’s Human Resources Division, health insurance union, and labor union come together to discuss management for health and well-being, with the Safety & Health Promotion Division acting as executive office.

In addition, activity reports are given and approvals are obtained in our Central Safety and Health Committee, which then spreads these measures to the Safety and Health Committees in each place of business.

Health Management Activities and Certifications/Awards

The ability of each employee to work with energy and health into the future is essential as a foundation to fulfill our corporate social responsibility as stated in Toyoda Gosei’s management philosophy. In recognition of this, we are promoting health management to maintain and promote the health of our employees.

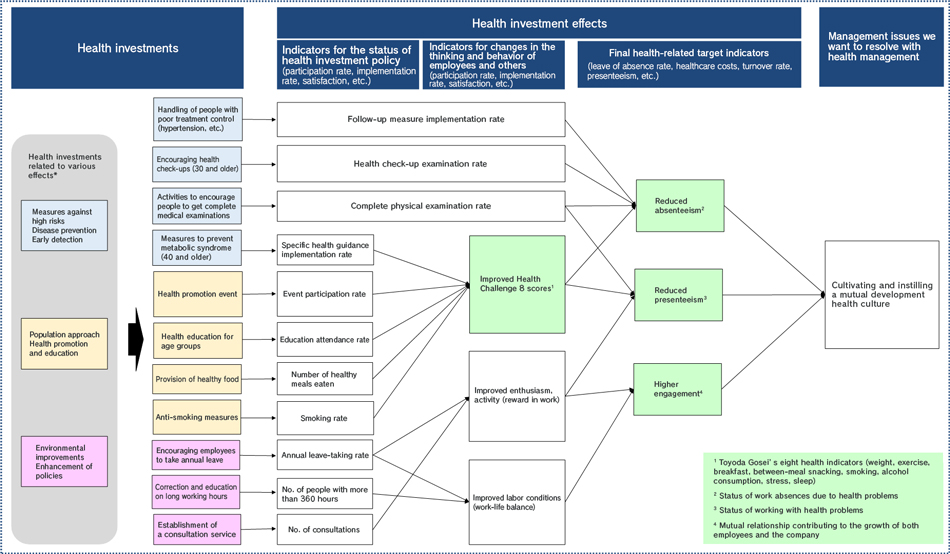

A strategy map based on the Ministry of Economy, Trade and Industry’s Guidelines for Administrative Accounting of Investment in Health and Productivity Management was created for the purpose of quantitatively showing health management initiatives and results, and implementing the PDCA cycle for activities. We will promote health management in a continuous and effective manner by quantitatively evaluating investments, effectiveness, and resources.

In Toyoda Gosei’s strategy map, “cultivating and embedding a health culture of mutual development” is set as a management challenge to be solved through health management. Activities are being conducted with the ultimate goals of (1) reducing absenteeism, (2) reducing presenteeism, and (3) increasing engagement.

Since FY2021, reducing presenteeism has been a special priority, and the company has been promoting health creation and education activities.

Assessment of health indicators

| FY2021 | FY2022 | |

|---|---|---|

| Presenteeism (University of Tokyo Single-Item Presenteeism Question) | - | 77.9% |

| Absenteeism (percentage of employees who miss ≥14 days of work) | 2.6% | 2.3% |

Health Challenge 8 in Health Management

As part of its commitment to fulfilling the corporate social responsibility outlined in the company’s management philosophy, Toyoda Gosei recognizes that it is essential for each employee to be able to work with energy and health into the future. To that end, it is engaging in health management to maintain and improve the health of employees.

Of the health KPIs defined in Health Challenge 8, stress, sleep and exercise had low scores and were designated as priority items. Various initiatives have been implemented for improvement in these areas, including presentations on sleep and stress and the distribution of videos to promote exercise by athletes in affiliate companies. In recognition of these efforts, Toyoda Gosei was certified as a Sports Yell Company 2023 by the Japan Sports Agency and as an Outstanding Health & Productivity Management Organization 2023 (White 500) by the Ministry of Economy, Trade and Industry.

- ※9 Health Challenge 8 is a metric consisting of the 8 items of weight, breakfast, alcohol, snacking, smoking, exercise, sleep, and stress

Exercise videos by Toyoda Gosei and affiliate company athletes

Raising Health Awareness and Changing Behaviors

We are in the eighth year of our workplace-based health promotion activities, one of the programs to achieve the goals in Challenge 8. The number of participants has increased year by year, and in FY2022 reached 97% of all employees.

Toyoda Gosei seeks to promote the health of its employees under the theme of “diet, exercise, sleep, and mental health,” which are the foundation of physical and mental well-being. Individual workplaces develop fun and creative ways to promote health and wellness. More than half of the 36 participating teams have adopted a theme of exercise, and interest seems to be rising.

The day of the annual health checkup is taken as a “Day to Think About Health,” and health education activities including a “health tip drawing” and grip strength measurements are held by public health nurses and other nurses.

Enhancement of Specific Health Guidance and Medical Checkups

2021 Specific health guidance implementation rate 82.7% (Active support implementation rate 68.6%, Motivation support implementation rate 96.9%)

In 2019 we adopted specific health guidance (active support) for groups in collaboration with the health insurance association. This led to a significant increase in the specific health guidance implementation rate, from 42.6% in 2018 to 81.0% in 2020. In regular health checkups, we began checking all employees using even tests that occupational physicians say could be omitted, for the early detection of anomalies and to establish healthy lifestyles.

In addition to health guidance by industrial physicians and others for employees with adverse health checkup findings, since FY2022 employees have received age-specific health guidance through interviews with a public health nurse every four years, regardless of whether or not any problems are found in health checkups. Opportunities are also provided for all employees to review their own health.

Dietary Improvements

In FY2021 we remodeled our company cafeteria with the concept “Eat delicious food and be healthy.” Healthy meals with lots ofvegetables and protein were incorporated in the menu, which was adapted to be both healthy and satisfying in terms of qualityand volume. A system was also introduced that allowed people to check on their smart phones the nutrition and calories in the meal they ate that day for self-management.

Initiatives to Maintain and Improve Women’s Health

Toyoda Gosei places importance on health management activities that support the health of working women.

The first “Women’s Health Lecture” for managers and female employees was held to improve their health literacy, and in March 2023 a special menu (Pink Ribbon Lunch) was offered in the cafeteria for “Women’s Health Week.” Information was also provided via panels, flyers, and digital signage to raise awareness of breast and uterine cancer screenings. The cancer screening rate is particularly low for women in their 20s, and in collaboration with the health insurance association leaflets are distributed to those women to encourage them to undergo medical checkups.

We are also trying to support women who are returning to work after parental leave by providing information on consultation services and self-care information to help them balance childcare and work from a health perspective. In 2022, a women’s consultation office staffed by female medical professionals (doctors, nurses) was also opened. This office also provides health consultations.

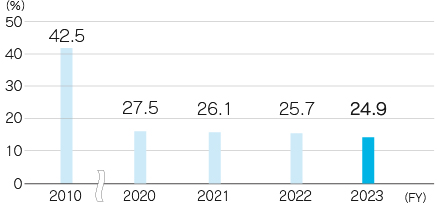

Anti-smoking Measures

With the aim of preventing health damage in smokers and passive smoking in non-smokers, we first banned the sales of cigarettes in the company (including vending machines). At the same time, we provided support by public health nurses to help smokers quit smoking. Since 2016 we have held “Smoking cessation talks” with invited outside instructors and held experience-based exhibitions that include measurements of lung age as motivation to quit smoking.

In anticipation of the Revised Health Promotion Act in Japan, which went into full effect in April 2020, we extended a smoking ban on all company property in the country starting in January 2020. At that time, the ban on employee smoking was not limited to company property but was extended to at least 100m from the property boundaries to prevent passive smoking by neighborhood residents. In cases when a nursery school or medical institution was in that zone, we expanded the ban zone to include the area around them.

To protect all people working in the company from passive smoking, we set a company policy with the aim of preventing harmful passive smoking. In addition to steady efforts beforehand to gain employees’ understanding, we made repeated requests to staffing agencies and contractors for their cooperation. Today, one year after the smoking ban on company property, its continuation has had no effect on productivity or employee retention.

The company-wide smoking rate has decreased from 42.5% in 2010 to 25.7% in 2022.

■Smoking Rate at Toyoda Gosei Co., Ltd.

Responding to and Preventing Mental Health Problems

Individual consultations by public health and other nurses and an employee assistance program (EAP)*9 (Ministry of Health, Labor and Welfare) have been introduced, and education for managers and supervisors is provided. Since FY2020 we have focused on sleep, since sleeping problems can be an early sign of mental health problems. Wearable devices are used to try to “visualize” the quality of sleep, and we are making efforts to prevent the recurrence of mental health problems by catching signs early.

We also provide “Health Orientation” education to new career employees within three months of joining the company, since physical problems are more likely to occur in people in those circumstances.

Learning the mechanisms of stress and methods for coping with it can help to prevent mental disorders.

- *9 Employee assistance program in which outside specialists support the mental health of employees

Stress checks and screening

A stress check system was introduced in FY2021, and a structure was set up that allowed people with high levels of stress to seek early assistance.

In addition to feedback on the results to individuals, group analysis result feedback is also provided to workplaces and advice is given about ways to improve the workplace.

| FY2020 | FY2021 | FY2022 | FY2023 | |

|---|---|---|---|---|

| Number of people who received checks (%) | 7,308 (96.0%) |

7,271 (93.3%) |

6,382 (95.5%) |

6,384 (94.6%) |

Prevention of Infections Among Employees

Subsidies for antibody tests for diseases such as measles and rubella were added to the company benefit system in 2020. Partial subsidies are also given for influenza vaccinations, including for family members.

In response to the novel coronavirus we have prepared infection prevention guidelines, update them as needed, and are spreading them globally to prevent infections. At the request of the government, we have also conducted workplace vaccinations four times in our headquarters district and the Morimachidistrict. To counter diseases such as AIDS (including HIV infection), tuberculosis, and malaria that are subject to notification based on the Infectious Diseases Act, our Crisis Management Guide details prevention and initial response methods and we are familiarizing employees with them.

Many Types of Health Education

Since FY2021, we have actively incorporated web-based education and have provided annual mental health education to all management workers. Since 2021 we have modified our educational programs to avoid the 3Cs (closed spaces, crowded places, close-contact settings) and promote mutual communication, such as by reducing the number of people in age-specific group physical health education*10 classes.

- *10 Aspects of physical health including various types of health checkup, prevention of lifestyle-related disease, anti-smoking measures, and various types of health promotion

| Name of training | No. of trainees/ participation rate (FY2022) |

|---|---|

| Health Up Seminar (30s) | 120 (92%) |

| Flexible Health Education (40s) | 125 (89%) |

| Mental Health Education (management) | 1,050 (95%) |

Responding to and Preventing Mental Health Problems

In 2018, we established TG Group Mental Health Activity Meetings and have promoted mental health activities at all subsidiaries. As a result, we have been able to carry out efforts including mental health education, contracts with psychiatrists, and the introduction of EAPs in each company.

From 2021, the name has been changed to Health Promotion Meetings and we have transitioned to activities that cover overall health, including physical health. Specific areas include (1) Planning targets for smoking bans on company grounds and support to achieve those targets, (2) information sharing and promotion of health creation activities, and (3) information sharing and promotion of mental health activities.

In addition, since 2022 smoking has been banned on the grounds of all 13 of the company’s domestic subsidiaries to further raise health awareness.

As a result of these efforts, two domestic subsidiaries received certification as a “2023 Health and Productivity Management Organization” (small and medium-sized business category).

![Company-Wide Average Overtime Hours[Toyoda Gosei Co., Ltd.]](img/social_graph_22.jpg)

![Number of Men Who Took Childcare Leave[Toyoda Gosei Co., Ltd.]](img/social_graph_24.jpg)

![Annual Paid Leave Taking Rate [Toyoda Gosei Co., Ltd.]](img/social_graph_23.jpg)