Supplier Relations

Supply Chain Management

The Toyoda Gosei Group has set a basic procurement policy based on the idea of coexistence and co-prosperity with our suppliers. We aim to deepen our partnerships with suppliers while achieving sustainable growth for us both.

1. Globally Optimized Procurement

We procure the optimum raw materials, products, and equipment fairly from a global perspective, taking into consideration cost, quality, technology, and production.

We also welcome proposals from suppliers for new technologies and manufacturing methods, and new products.

2. Mutual Development Based on Mutual Trust

We aim to enhance the collective strength of the Toyoda Gosei Group based on open and fair relationships with our suppliers, mutually enhancing our corporate structures, innovating our management, and building relationships of mutual trust.

3. Efforts for a Sustainable Society

Toyoda Gosei has set activity norms as guidelines for initiatives that should be made for the SDGs and other social issues, and shared them with suppliers in carrying out activities.

We also aim to ensure complete legal compliance and confidentiality in corporate operations, including our supply chain.

Our Supply Chain

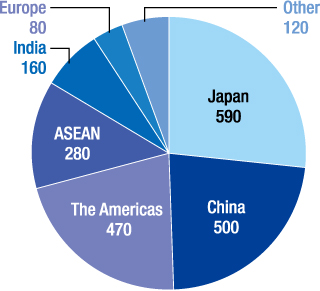

Toyoda Gosei directly conducts transactions with approximately 600 suppliers, and globally, including overseas locations, the number exceeds 2,000 suppliers.

In our global business operations, we consider all aspects of SQDC (Safety, Quality, Delivery, and Cost) and are working to enhance collaboration among procurement personnel in each region to further implement local procurement.

■Number of Suppliers by Region

Enhancing Global Collaboration

To achieve the goals of our 2030 Business Plan, we have been working to enhance our global procurement collaboration system since FY2024. We aim to align procurement strategies across regions—Japan, the Americas, Europe, ASEAN, China, and India—with the strategies of each business division combined to enhance competitiveness.

Strategies formulated at top-level meetings, including local representatives, are further detailed through discussions at the operational level, which include on-site visits. These efforts are implemented using a PDCA cycle.

Moving forward, we will continue to implement region-specific collaboration methods to improve procurement functions, advance sustainability initiatives, and enhance partnerships with local suppliers.

Business with New Suppliers

We have an entry form on our website for open dialogue regarding new proposals and business dealings. In addition to SQDC assessments at the start of new business dealings, we also check the status of the other party’s management activities based on their level of support for our sustainability guidelines and other factors, to manage risks starting from our first transactions. At the same time, together with the signing of contracts and memorandums of understanding, we explain the various guidelines that Toyoda Gosei has developed and seek their understanding.

New Supplier Assessment

We have established and are implementing internal rules for selecting new suppliers when we start doing business with them.

In addition to examining a potential supplier’s financial conditions and other factors, we also check the status of their quality management certification, such as ISO9001 and IATF16949, and investigate sustainability issues to determine whether or not to initiate business with them.

Initiatives With Suppliers

Initiatives for Sustainability Over Entire Supply Chain

Recognizing the growing expectations for corporate sustainability initiatives, we have developed and shared the Supplier Sustainability Guidelines (2nd Edition) with our suppliers to promote understanding and practical implementation, and requested their support.

To enhance awareness of potential risks and encourage early countermeasures, we provide self-check sheets for suppliers to conduct self-assessments. Moving forward, we will collaborate with suppliers to implement improvements based on the assessment results.

The Guidelines set policies related to human rights, labor, the environment, compliance, and other matters.

In addition to social aspects (including eliminating child labor, forced labor, and discrimination, and ensuring equal opportunity, reductions in long working hours, and compliance with minimum wage laws), the Guidelines also require compliance with environmental aspects such as water use and biodiversity by suppliers.

With regard to the environment, our Green Procurement Guidelines require suppliers to reduce CO2 emissions, recycle resources including waste, and manage chemical substances.

For conflict minerals, we ask suppliers to be responsible in their procurement of resources and raw materials, and once a year, we conduct a survey on conflict minerals with the cooperation of all suppliers.

As described above, we are accelerating initiatives needed for sustainable growth over our entire supply chain, matched to the various changing social conditions.

We are also working in collaboration with all our locations to globally expand the Supplier Sustainability Guidelines by incorporating regional characteristics.

- Key contents of Supplier Sustainability Guidelines

- Human Rights, Labor

- Ethics and Compliance

- Safety and Quality

- Risk Management

- Information Management

- Environmental Initiatives

- Responsible Procurement of Materials

- Social Contribution

- Promotion of Sustainability Activities

Responsible Procurement of Materials

With the globalization of business, supply chains are becoming increasingly global and diversified. However, places where workers’ rights are not taken into consideration still exist in the world, including forced labor and labor in poor conditions.

As one example of this, Toyoda Gosei recognizes the problem of conflict minerals mined under poor labor conditions, and this is an important issue in our supply chain.

Toyoda Gosei conducts a conflict minerals survey once a year with the cooperation of all relevant suppliers. Survey forms are submitted by suppliers targeted for surveys each year, and no serious matters related to conflict materials have been seen in the responses of the suppliers surveyed.

As the market changes and the targeted minerals increase, we will regularly review the risk targets and consider how best to respond as a company.

In the Supplier Sustainability Guidelines (version 2), suppliers are required to conduct responsible resource and raw material procurement.

We will continue to work with our suppliers to avoid the use of minerals of concern throughout our supply chain.

Environmental Risk Assessments

● Environmentally hazardous substances

To ensure compliance with environmental regulations, Toyoda Gosei works with suppliers to investigate the chemical substances contained in the products they deliver to us.

● New suppliers

As part of our environmental risk assessment of new suppliers, we check whether they have obtained ISO14001 or third-party certification before starting to do business with them. In cases when certification has not been obtained, we check for compliance with Toyoda Gosei’s own guidelines. If there are items that are not in compliance, we request corrective action and confirm the results.

Anti-bribery Initiatives

The Toyoda Gosei Group has established the Global Anti-Bribery Guidelines based on the Toyoda Gosei Group Charter of Corporate Behavior, and the entire Toyoda Gosei Group endeavors to prevent bribery, accounting irregularities and other corrupt practices. We also demand that all suppliers doing business with Toyoda Gosei not engage in bribery in their relations with government or administrative officials, and not give or receive gifts of entertainment or money to or from third parties for the purpose of obtaining or maintaining unfair advantages for the Toyoda Gosei Group.

Implementing Carbon Neutrality Initiatives

To achieve the carbon neutrality goals in our 2030 Business Plan, we recognize the importance of reducing Scope 3 emissions, which account for 70% of our CO2 emissions. In collaboration with 140 key suppliers of product components, equipment, and molds, we are actively engaging in initiatives to understand their current states and challenges while maintaining close communication. Specifically, to help each supplier formulate reduction themes, we share our Energy Saving Casebook, host study sessions at our Energy Saving Dojo, and lend out various measuring instruments. We are also supporting suppliers in developing roadmaps to achieve medium- to long-term goals, including a 27% reduction by FY2030 and net zero by FY2050.

As part of these efforts, we hold the Carbon Neutral Initiative Conference twice a year, where group discussions among suppliers facilitate information sharing and problem-solving. From FY2024, we have begun globally expanding Japan’s initiatives, and we will continue working toward decarbonization across the entire supply chain.

Enhancing Our Partnerships with Suppliers

Every April, we hold procurement policy briefings where we explain our management philosophy, the business environment and company policy to about 250 of our major suppliers in Japan. After sharing our initiatives, challenges, and targets related to SQDC, compliance, and sustainability, we hold regular discussions to confirm results and make improvements through anticipated value roundtables.

In addition, starting in FY2019, we take December of each year as an opportunity to express our gratitude and respect to our suppliers and to listen to their honest opinions with humility. We aim to build better relationships with our suppliers by presenting them with letters of appreciation to express our gratitude for their daily efforts.

We also hold procurement liaison meetings every month, where we introduce case studies on initiatives such as fire prevention, disaster preparedness, compliance, and cybersecurity. In addition, we conduct seminars on carbon neutrality and other social issues.

In FY2020, we established Management Troubleshooting Consultations for suppliers and other business operators. We receive candid inquiries from them on various management issues, including corporate management, finance, human resources, and legal matters. This is done in small groups, where we try to give advice on effective solutions.

These support consultations have exceeded 200 sessions, gradually fostering natural connections among suppliers. By sharing challenges, a positive cycle of mutual learning and collaboration has emerged.

Supplier Evaluation System

Toyoda Gosei has established a supplier evaluation system and presents awards to suppliers who have performed exceptionally with regard to quality, price, delivery, technology, and the environment.

The company also seeks to strengthen foundations in tandem with the supply chain. One example this is the presentation of certificates of appreciation to suppliers for their ongoing efforts to improve production activities.

Support for Suppliers So That We Can Grow Together

To support our suppliers, we implement various initiatives from the perspective of SQDC. Particularly in terms of safety, we are implementing fire prevention inspections for production equipment such as painting systems and proactive prevention initiatives based on risk assessments. For quality and production, we are conducting on-site improvements through manufacturing innovation initiatives, all while linking these efforts to talent development support.

We are implementing these initiatives in association with talent development support, such as transfer of our own skilled workers or accepting core personnel from our suppliers.

In addition, we provide indirect support for the initiatives of the Kyowa-kai, which is organized by suppliers for the purpose of mutual learning and sharing of best practices.

From 2022, the Winning (Value) Technology Exhibition has been hosted by the Kyowa-kai with the aim of enhancing the competitiveness of both parties by utilizing suppliers’ accumulated knowledge. Companies have shared ideas, resulting in significant improvements.

To further enhance collaboration and accelerate progress, in 2023, we also began to leverage the strengths of both parties by sharing information on our problems (needs) and the proposals (seeds) of the Kyowa-kai. At the FY2024 Winning Technology Exhibition, we showcased many collaborative achievements, including those involving multiple suppliers.

Toyoda Gosei Kyowa-kai

The Toyoda Gosei Kyowa-kai is a cooperative association established in 1970 in response to growing social needs for quality. Its aim is the mutual development and prosperity of Toyoda Gosei and our major suppliers. The Kyowa-kai consists of three subcommittees: Equipment & Molds, Rubber & Metals, and Plastics. It conducts various activities in cooperation with Toyoda Gosei, such as holding subcommittee meetings on quality, fire prevention, disaster prevention and safety; workplace improvement and QC circles presentations; participation in Toyoda Gosei level-specific education and domestic and overseas training; and a year-end meeting with company top management.

Partners in together creating future value

Since 1970, the Kyowa-Kai has been working together with Toyoda Gosei, and all companies involved have refined their own technology while meeting Toyoda Gosei’s needs, including for safety, quality, and defect reduction. However, as the automotive industry undergoes major changes, we believe that it is essential to review the association’s activities in order to increase competitiveness. We decided to set a new direction through serious discussions among members, for example through young people’s study groups. The first step in this process is the establishment of a philosophy that clearly states the goals of Kyowa-kai and the launch of three committees. All of these committees are led by members of the Kyowa-kai and are characterized by voluntary activities.

Kyowa-kai is not only an association that focuses on day-to-day production activities, but also a partner that takes a long-term perspective and together creates future value for Toyoda Gosei. We will use these strengthened activities as an opportunity to actively exchange opinions with people at Toyoda Gosei to enhance our partnership and promote activities for the realization of Toyoda Gosei’s business strategy.

Shigemitsu Kondo

Shigemitsu KondoPresident of Kondo Seisakusho Co., Ltd. Chairman, Toyoda Gosei Kyowa-kai

Collaborating with Toyoda Gosei with the aim of growth for both of our companies

The Kyowakai directs its attention toward innovation rather than maintaining the status quo, and its activities aim for the creation of the mechanisms and systems that respective companies need as a partner to Toyoda Gosei, suited to the changing times and circumstances.

We have thought about how we can be the best partners to Toyoda Gosei, and have begun efforts such as the long-term development of each member company’s unique technology and the growth and development of employees.

Each member company participates in the three committees, “Human Resources Development,” “Carbon Neutrality,” and “One Team, One TG,” and conducts activities not only to incorporate the content of the information provided by Toyoda Gosei into our own activities but to transform it into initiatives that are brought out by each company. As a result, we promote collaboration that begins with each company sharing the content of its activities with Toyoda Gosei.

Many examples of this were presented at the FY2023 “Winning Technology Exhibition.” Toyoda Gosei and member companies will continue to carry out these activities to raise added value with the many different technologies that the two sides possess, and we will continue these activities as indispensable partners of Toyoda Gosei going forward.

Yoshinori Kotsuka

Yoshinori KotsukaPresident, Kozuka Techno Co., Ltd.

Vice Chairman, Toyoda Gosei Kyowa-kai

Supplier Training

Companies in the sustainability field face a rapidly changing environment, and we believe it is important for the entire supply chain to understand current trends and take appropriate actions. This is why we conduct training for our major suppliers.

Briefings on topics such as overall sustainability, the environment, and human rights, as well as carbon neutrality and enhanced cybersecurity, are held as appropriate to ensure that our major suppliers understand the importance of these initiatives throughout the supply chain.

Monitoring of Supplier Information

We request suppliers with whom we have ongoing transactions to submit a survey sheet covering management information at least once a year, and we strive to quickly resolve risks and solve problems by visiting and interviewing suppliers regarding major changes.

In addition, based on annual evaluation results, we conduct on-site audits once a year at suppliers that meet our selection criteria in areas such as quality and safety. These audits are aimed at driving improvements.

Company Internal Initiatives

Employee Education and Training

We strive to follow the “Toyoda Gosei Guidelines for Business Ethics” so that each and every employee engaged in procurement operations can conduct their activities in a manner that is open, fair and equitable toward suppliers.

To achieve sustainable societies, we also make efforts throughout our supply chain with a view to social issues and circumstances. The Procurement Subcommittee holds regular monthly meetings to ensure that procurement activities correspond to various changing social conditions, and all Purchasing Division members are given compliance (subcontracting laws, bribery, etc.), safety, and carbon neutrality information.

Participation in Relevant Associations and Initiatives

We participate in industry associations such as the Japan Auto Parts Industries Association (JAPIA) and the Japan Rubber Manufacturers Association (JRMA). Our company president serves as an officer (director) of JAPIA.

Through our activities in these industry associations, we seek to achieve sustainable growth together with our suppliers, such as through the Declaration of Partnership Building promoted by the Ministry of Economy, Trade and Industry.

We are also participating in the revision of the JAPIA BCP Guidelines by the general affairs committee of JAPIA for not only earthquakes but also wind and water damage and pandemics. In this and other ways we are contributing to the formulation of BCPs by suppliers in the auto parts industry.

Ensuring Fair Transactions

In our Declaration of Partnership Building, we pledge to engage in discussions with suppliers regarding the appropriate pricing of labor and rising energy costs.

We proactively reach out to suppliers, working closely with them through repeated consultations to address and resolve challenges.

Declaration of Partnership Building

In August 2020, Toyoda Gosei announced its participation in the “Declaration of Partnership Building” framework of the Cabinet Office, the Ministry of Economy, Trade and Industry, and others. A Declaration of Partnership Building is a declaration of mutual prosperity for the entire supply chain, and new cooperation that transcends scale, affiliation, and other factors.

Declaration of Partnership Building