Functional Components

- HOME

- Functional Components

These rubber and plastic components support the basic vehicle functions of driving, turning and stopping. Toyoda Gosei technology ensures quality for these key safety-related parts.

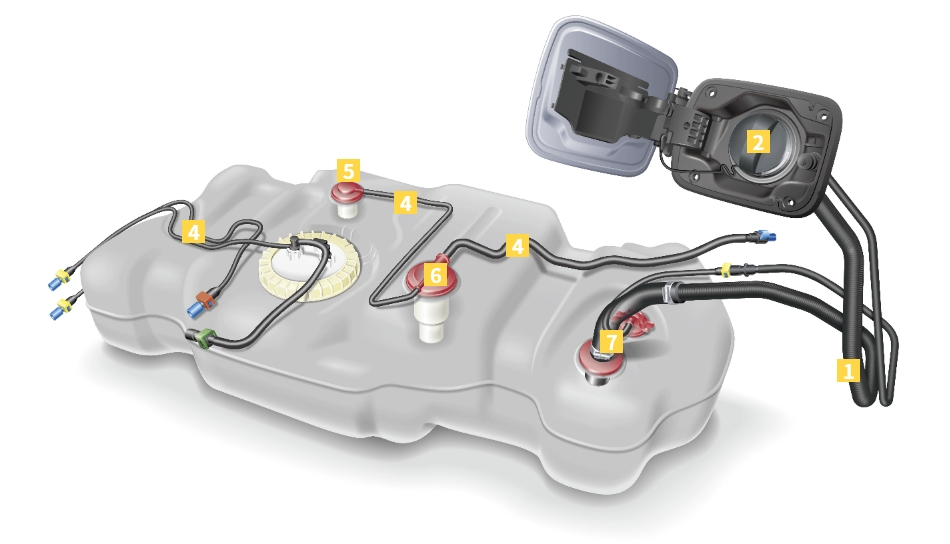

Fuel Components

1Plastic fuel filler pipes

Single-piece molding of sections with different characteristics (flexible, rigid, and straight sections) assures the strength of these pipes, while their multi-layer structure improves fuel resistance and durability. These technologies have made it possible to reduce weight by nearly 50% compared with previous metal pipes.

2Fuel filler caps

These caps are attached to prevent fuel leakage from the intake port when the gas pump nozzle is inserted, by functioning as a seal.

3Capless fuel fillers

A device designed to make refueling more convenient by simply inserting the nozzle without opening or closing the filler cap when refueling.

4Fuel hoses and tubes

These rubber and plastic pipes send fuel to the engine and fuel vapor to the atmosphere via the fuel vapor cleaner.

5Cutoff valves

These valves prevent the elevation of pressure inside the tank by releasing vaporized gasoline when the internal temperature rises. The number used on a vehicle has been reduced by raising the ventilation performance with a modified structure, contributing to lighter weight of the fuel tank overall.

6Fill limit vent valves

These valves restrict the amount of fuel when the tank becomes full, functioning to seal and prevent variation in fuel levels.

7Inlet check valve

Check valves prevent fuel from flowing backwards out of the fill tube opening when the tank becomes full.

8High pressure hydrogen tanks

One of the main components of fuel cell electric vehicles (FCEVs). Hydrogen is compressed to a high pressure (about 700 atm) and efficiently stored.

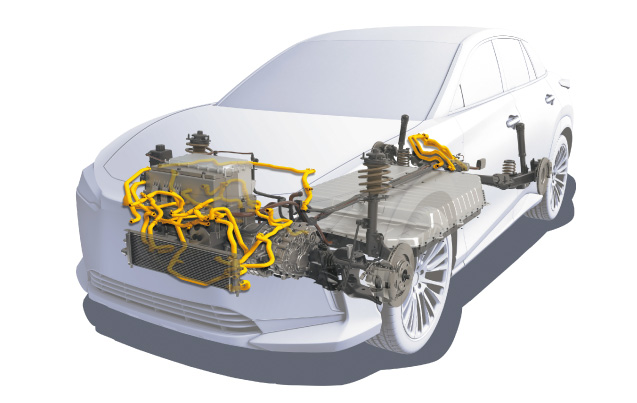

Battery Components

09Cooling pipes

Maintaining batteries at the proper temperature leads to longer battery life, while also contributing to increased driving range.

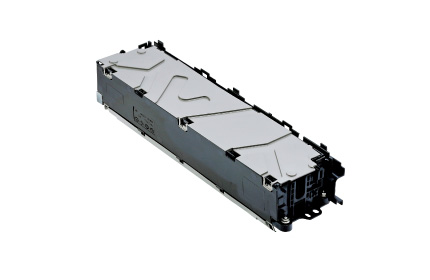

10Battery cases

Battery case made of plastic stores multiple batteries.

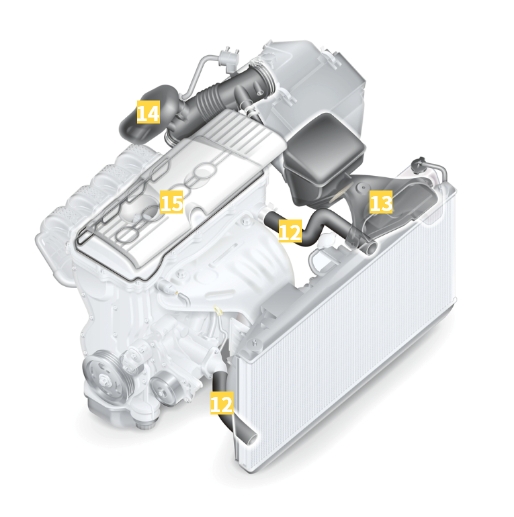

Engine Components

11Plastic turbo ducts

These pipes send compressed air to raise engine output. In addition to withstanding high pressure and temperature, they absorb engine vibrations. (Long, complex pipes are blow formed with plastic, reducing weight by about 50%.)

12Radiator hoses

These hoses connect the engine and radiator for the circulation of the coolant that is needed to cool the engine.

13Noise absorbing air intake ducts

These ducts take in outside air needed in engine revolution. Intake noise is reduced with the use of air permeable members in part of the duct.

14Air cleaner hose with resonator

Air cleaner hoses are used in providing the clean air needed for engine revolution. Resonators reduce the noise that is generated when air is taken in.

15Engine covers

By covering the top of the engine, these covers make the engine compartment more aesthetically pleasing and reduce noise from the engine itself.

16Plastic water pipes

These pipes are placed around the engine. They include several types with different functions. They are used for air conditioning, oil cooling, turbo cooling, and other functions.

Chassis and Drive Train Components

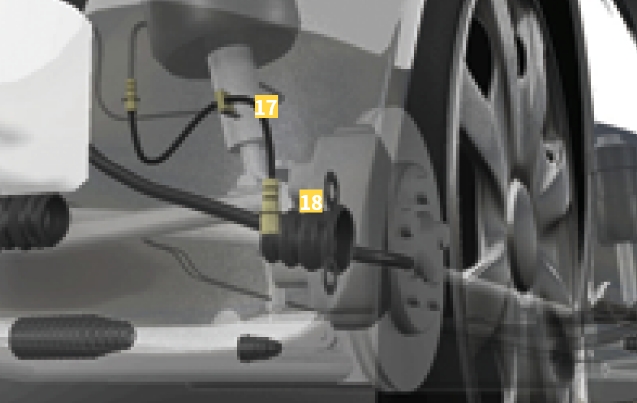

17Brake hoses

These hoses transmit hydraulic pressure in the body-side brake system to the wheel-side brake system. They are flexible and highly durable so that they can follow the movement of the wheels.

18Constant velocity joint boots

These boots have a cylindrical, bellows shape and are used to cover constant velocity joints, which turn and flex. They keep joint lubricating grease in and water and dirt out.

19Oil pumps

These pumps suction up and circulate oil to reduce friction in the transmission gears and bearings. Leveraging our plastic precision molding technology, we have made the gears and other oil pump components of plastic and reduced mass by about 30%.