Building a Recycling-Oriented Society

Basic Philosophy

In order to mitigate resource depletion and water risks, we not only take measures for defects and yield, which are the focus of our manufacturing divisions, but also work on emission control and recycling involving material and production technologies in the sourcing divisions for contributing to the attainment of a recycling-oriented society. For water, we identify risks in each location where we conduct business globally while also striving to reduce risks by reducing water usage, recycling water, and returning cleaner wastewater to the community.

Risks and Opportunities Related to Resource Recycling

We consider risks and opportunities related to resource recycling as important management issues, and we are working on them company-wide as one of our priority issues to be addressed.

| Issue | Risks | Opportunities | Response |

|---|---|---|---|

| Resource depletion (shortage) |

|

|

|

| Water risk (quantity and quality) |

|

|

|

Reduction of Industrial Waste

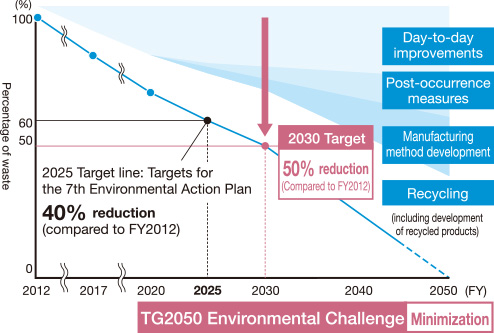

Establishment of 2030 Milestones

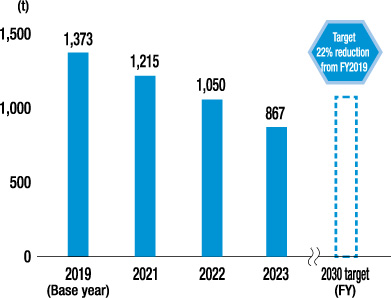

We are working to reduce industrial waste through measures such as curbing emissions, addressing sources of waste, recycling rubber and plastic scraps, and ensuring thorough sorting to maximize resource utilization.

■Milestones for Minimizing Waste Volume: Global

| Item | 2025 | 2030 | 2050 (FY) |

|---|---|---|---|

| Toyoda Gosei (Waste Volume) |

Compared to FY2012: 40% reduction |

Compared to FY2012: 50% reduction |

Minimization of waste volume |

| Overseas affiliates (Waste volume per unit sales) |

Compared to FY2015: 50% reduction |

Compared to FY2015: 55% reduction |

■Scenario for Minimizing Amount of Waste (Waste Reduction Diagram) [Non-consolidated]

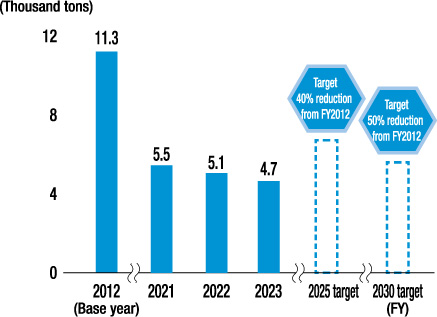

■Industry waste volume (Toyoda Gosei)

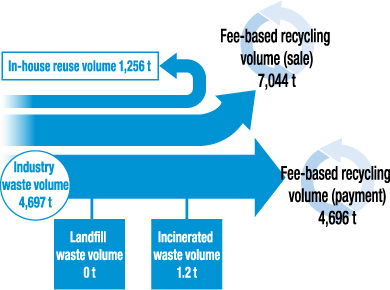

■Waste Volume per Unit Sales (index*1) (Overseas affiliates)

- *1 Figures based on the base year as 100

Development of Product Recycling Technology

- Materials

- Design

- Manufacturing

- Recovery/recycling

We develop and design easily recyclable products and materials with consideration of the entire lifecycle of automobiles. We are also developing recycling technology for waste material and ELV parts.

■Technology Development for Recycling ELV*3 Parts

| Key item | Measures implemented |

|---|---|

| New recycling |

|

| Use of recycled materials in vehicles |

|

| Design of easily-recyclable products |

|

- *3 ELV: End of Life Vehicle

Reduction of waste materials in the production stage

- Manufacturing

- Collection/recycling

The company’s production engineering and manufacturing divisions are working together to reduce waste in the production stage, combating waste at its source and encouraging recycling. At each plant, we are conducting inspections for all types of waste to identify items for reducing waste by using the genchi-genbutsu system (collecting facts and data at the actual site of the work or problem) to implement waste reductions. We also share examples of waste reduction with both domestic and international Group companies to implement waste reduction throughout the entire Group.

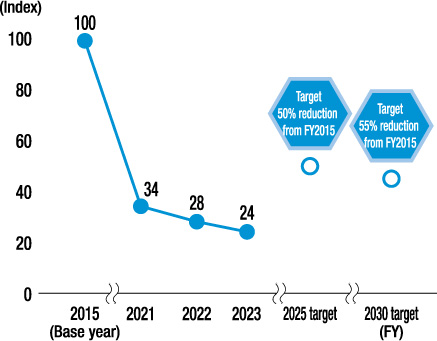

■Industry waste generation and disposal (FY2023 result) (Non-consolidated)

Examples:(5) Building a recycling-oriented society_Reduction of waste materials in the production stage

Reduction of Packaging Materials in the Distribution Stage

- Collection/recycling

By washing returnable boxes*2 more frequently and keeping them clean, we are reducing the amount of packaging materials used to prevent products from being soiled. We are also reducing packaging materials by putting lids on returnable boxes and making other changes while maintaining a balance between ensuring product quality and reducing the amount of packaging materials used.

- *2 Boxes for transporting products

Satisfying the Plastic Resource Circulation Act

The Plastic Resource Circulation Act went into effect in April 2022, and with a view to our contribution to carbon neutrality, we are committed to designing and manufacturing environmentally friendly 3R + Renewable products.

■Plastic Industrial Waste Volume (non-consolidated)

Examples:(6) Building a recycling-oriented society_Development of product recycling technology

Reducing Water RisksManufacturing

Establishment of 2030 Milestones

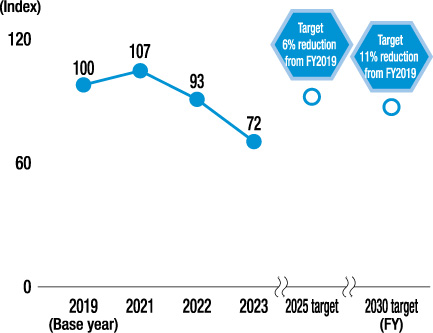

We are assessing risks in both water usage and water quality in Japan and international locations, and making improvements at high-risk locations. Even in locations where risks are low, we are trying to reduce water intake amounts for the effective use of resources.

Since FY2021, we have been working to reduce water use by reducing leakage and implementing wider recycling.

We are also working to systematically upgrade our wastewater treatment facilities to produce even cleaner wastewater.

■Water Intake per Unit Sales (index*4) (non-consolidated)

- *4 Figures based on the base year as 100

■Milestones for Minimizing Water Risk: Global

| Item | 2025 | 2030 | 2050 (FY) | |

|---|---|---|---|---|

| High-risk areas | Water quality (4 sites) | Measures implemented at 2 sites | Measures implemented at 4 sites (all sites) | Minimization of water risk |

| Water intake amount (7 sites) | Measures implemented at 3 sites | Measures implemented at 7 sites (all sites) | ||

| Low-risk areas | Compared to FY2019: Water intake per sales unit: 6% reduction |

Compared to FY2019: Water intake per sales unit: 11% reduction |

||

Data for the past three years >>> Environmental Data

Examples:(7) Building a recycling-oriented society_Reducingwater risks

- Contributing to Environmental Preservation Through All Our Business Activities

- Environmental Action Plan

- Building Decarbonized Societies

- Building Circular Societies

- Environmental Preservation and Building Environmentally-Friendly Societies

- Environmental Management

- Collaboration with External Organizations

- Environmental Efforts at Affiliated Companies

- Environmental Data

- Third-Party Verification

- TCFD

- Third-Party Assessment