To Individual Investors

- HOME

- Investor Relations

- To Individual Investors

- Growth Strategy

Growth Strategy

2030 Business Plan explanatory materials [PDF]

The Company We Want to Be in the 2030 Business Plan

Pursuing the possibilities of polymers, we will contribute to a future of better mobility and living

Our business centers on automotive parts using our core rubber and plastic polymer technology.

We respond to the needs of society by supplying diverse products and value.

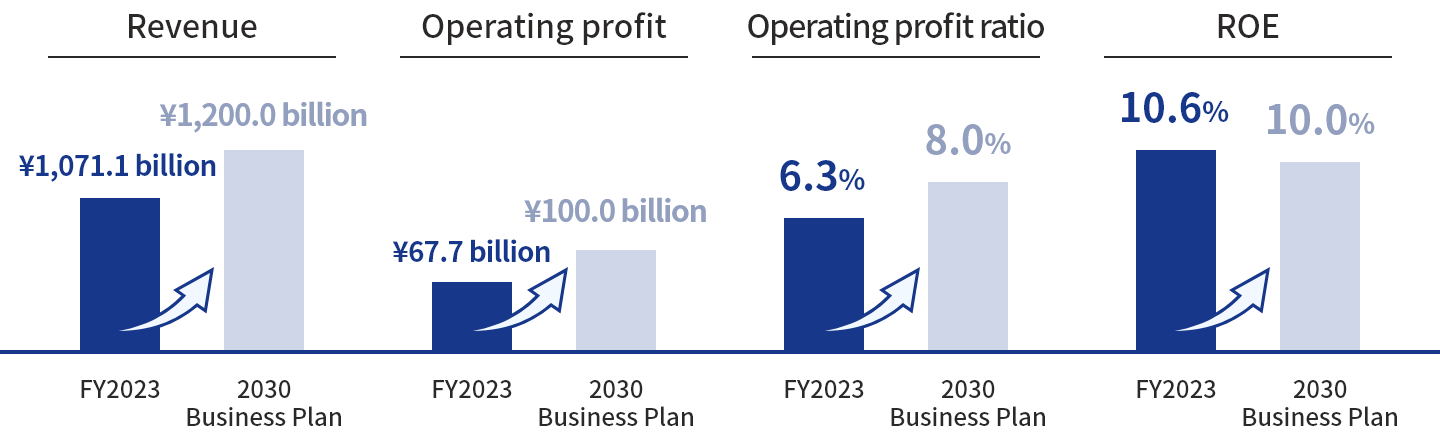

FY2030 financial objectives

Changing Mobility in Society (Background for the Development of the Plan)

Values provided by Toyoda Gosei

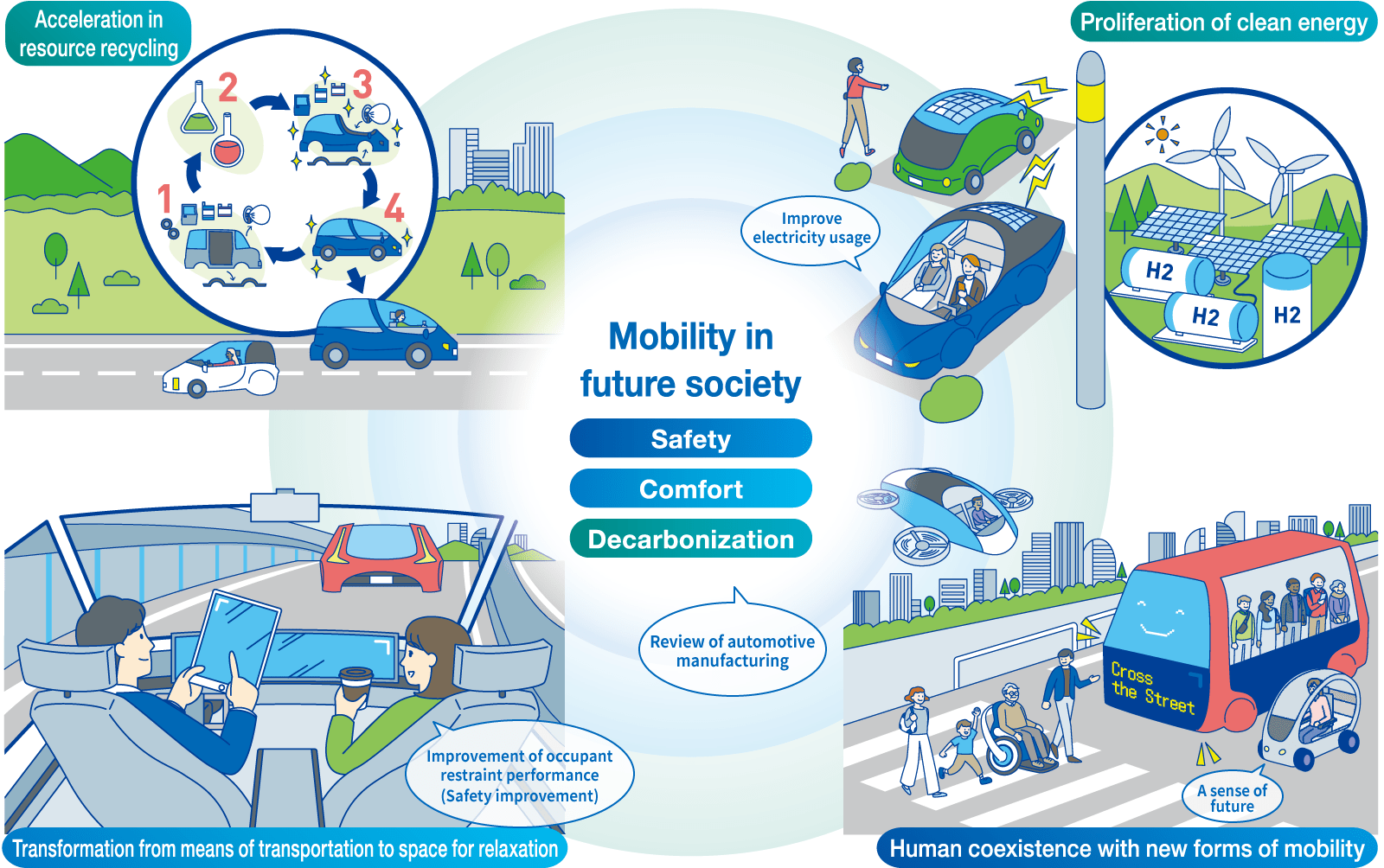

We believe that four changes will have occurred in mobility by 2030: acceleration in resource recycling, proliferation of clean energy, transformation from means of transportation to space for relaxation, and human coexistence with new forms of mobility. In response to these changes, we aim to contribute to society by providing the three values of safety, comfort, and decarbonization.

Efforts to Provide Value

Mobility

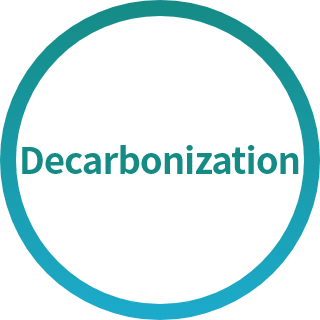

Achieving further growth with coordination among our key businesses (safety systems, interior and exterior products) and key regions (North America, India)

Toyoda Gosei is shifting resources to growth fields that provide both social and economic value as we move toward mobility in 2030. Our particular focus is on the business of safety systems and interior and exterior products, and the regions of North America and India.

Click the numbers in the chart below to see detailed information.

Information on mobility

Here you can view the initiatives and technologies that are focuses for Toyoda Gosei.

Contributing to safety

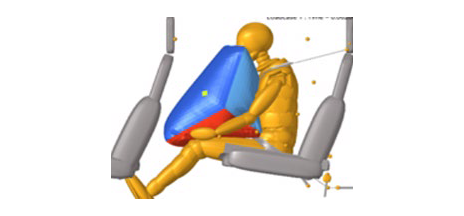

By providing various types of airbags, we have contributed to a reduction in the number of fatalities from traffic accidents. Going forward, we will not only evolve existing seatbelts and airbags to higher levels, but will also develop new products such as next-generation steering wheels with the human-machine interface (HMI) functions that will be needed for self-driving and lap airbags that raise the degree of freedom in vehicle occupant postures.

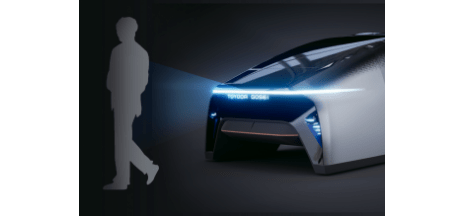

We are also developing non-automotive products that help to solve social issues related to safety on the road, such safety devices for electric scooters and other new forms of mobility, and those to assist in falls and other pedestrian accidents.

Contributing to comfort

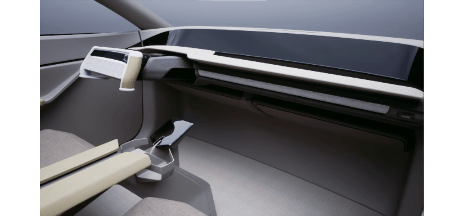

Toyoda Gosei combines safety system illuminated products with interior and exterior products to provide new functions suited to BEVs, including communication with other vehicles and pedestrians and the creation of pleasant spaces during autonomous driving. By leveraging our polymer technology in attempts to make products of plastic materials, we are also making these products lighter in weight, which contributes to longer driving range.

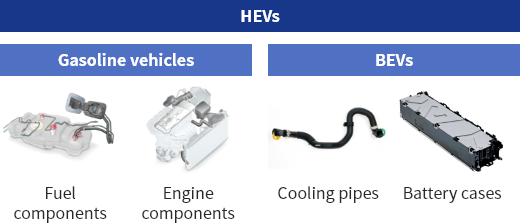

Contributing to heat management

Leveraging our knowledge of fuel components and engine components for internal combustion engine vehicles, we supply battery electric vehicle (BEVs) products that manage heat, such as cooling pipes and battery cases, as we respond flexibly to the changes in mobility.

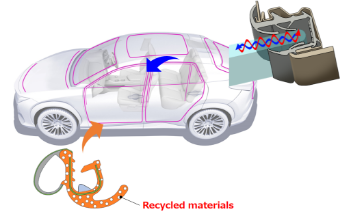

Contributions to quietness, rubber recycling

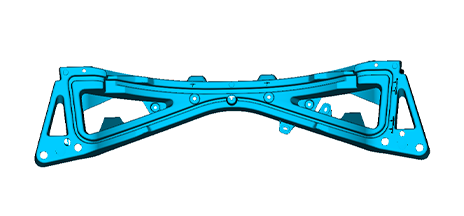

Even with the transformation of automobiles, weatherstrips will still be attached to door and window frames to keep out wind, rain, and noise. These weatherstrips also contribute to comfort during vehicle operation, and can block noise from the outside from things such as vibration and transmitted sound. In addition, rubber products, which are difficult to recycle, can now be reused with our original devulcanization and regeneration technology. In this and other ways we are also contributing to a decarbonized society.

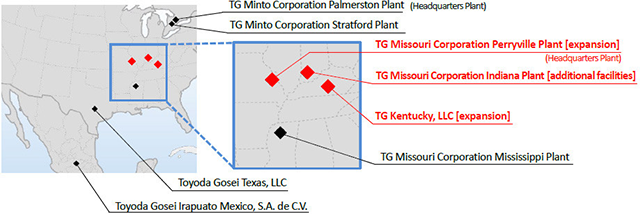

Interior and exterior products account for about 40% of the sales of Toyoda Gosei’s North America business. The company will continue to watch the progress of battery electric vehicles (BEVs) and various other types of vehicles being launched by automakers, and will expand plant buildings at subsidiaries TG Missouri Corporation and TG Kentucky, LLC (start of operations planned for December 2025) to establish a network that can provide products with a wide range of variations.

In India, the equipping of vehicles with airbags for protection in frontal collisions (driver side airbags, passenger side airbags) has been increasing for some time, and sales are expected to continue growing in the future. The equipping of new vehicles with airbags for protection in side collisions (side airbags, curtain airbags) is also expected to increase, and we aim for growth greater than the number of vehicles produced.

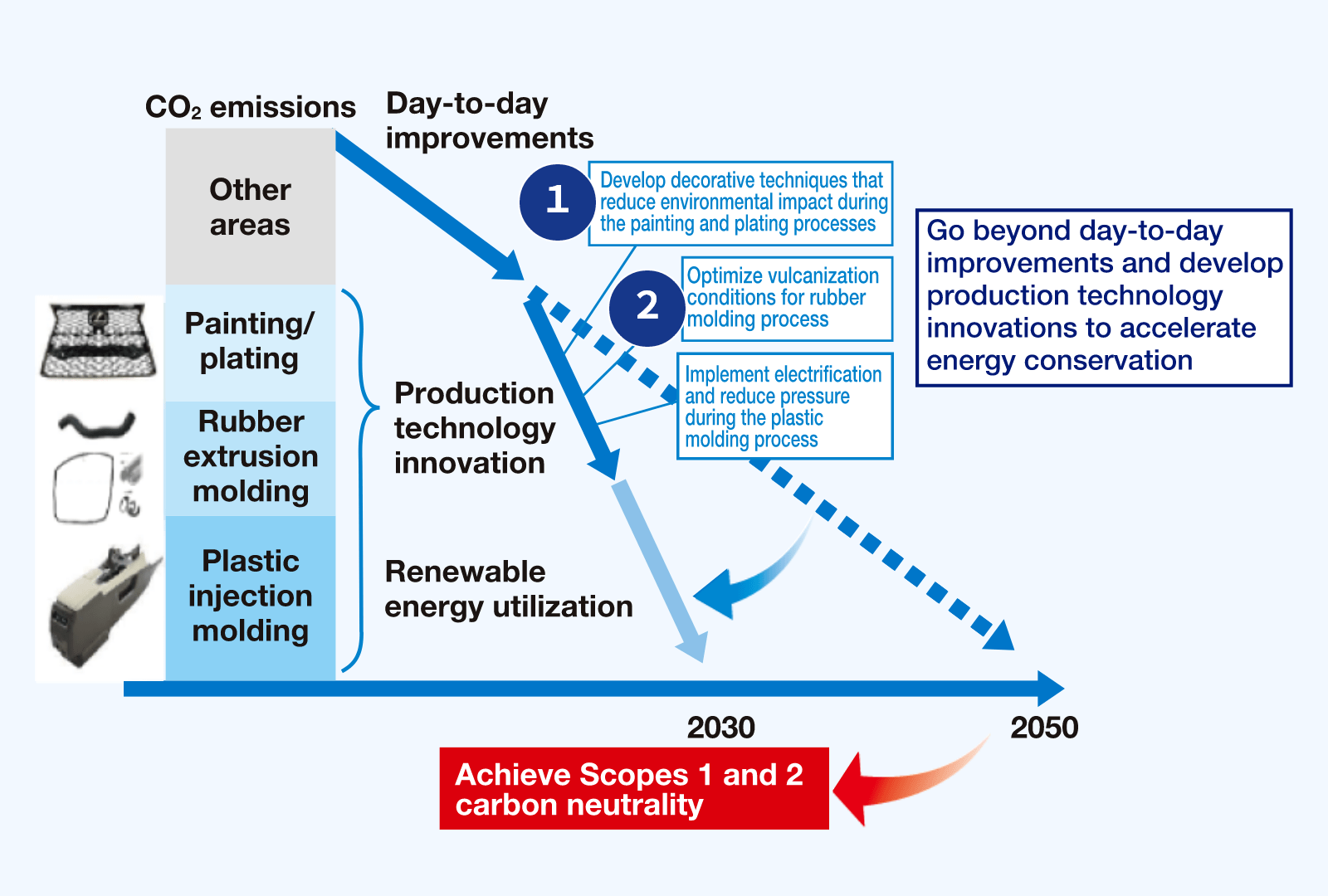

Decarbonization

To help mitigate the risks of climate change, which are becoming more serious in all parts of the world, we have brought forward our original target of achieving carbon neutrality by 2050 to a much earlier target year of 2030. We aim to achieve carbon neutrality by daily kaizen, innovations in production technology, and the use of renewable energy.

Click the numbers in the figure below to see Toyoda Gosei’s initiatives for decarbonization.

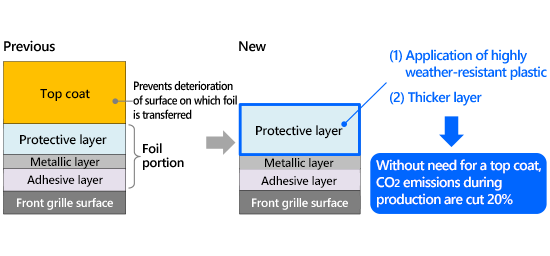

Hot stamping

This is a technology that transfers foil to products with heat and pressure to give a metallic texture. It enables spot decoration of places with a small surface area, such as highlights on a front grille. Leveraging our knowledge of plastic materials, we apply highly weather-resistant plastic in the protective layer of the foil. Making this layer thicker means that a conventional top coat is no longer necessary, and the elimination of this process cuts the amount of CO2 emitted during production by 20%.

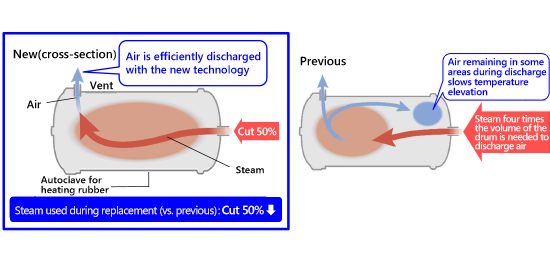

Reducing the amount of steam used in the manufacturing process for rubber products

To impart elasticity to rubber automotive hoses, after the molding process hoses are placed in large drums filled with high temperature steam and heated. A large amount of steam is needed to raise the temperature to the designated level, and much gas is consumed in the process of creating that steam. We therefore developed a technology to efficiently discharge the air in the drum in the process of replacing the air with steam. The amount of steam (CO2 emissions) needed during this replacement was cut in half compared with the previous process.

Information on decarbonization

Here you can view initiatives and technology with a focus on decarbonization.