News

April 22, 2024

For safer living with improved performance as a light source for disinfection

Toyoda Gosei Develops UV-C LED with World-Class Light Output

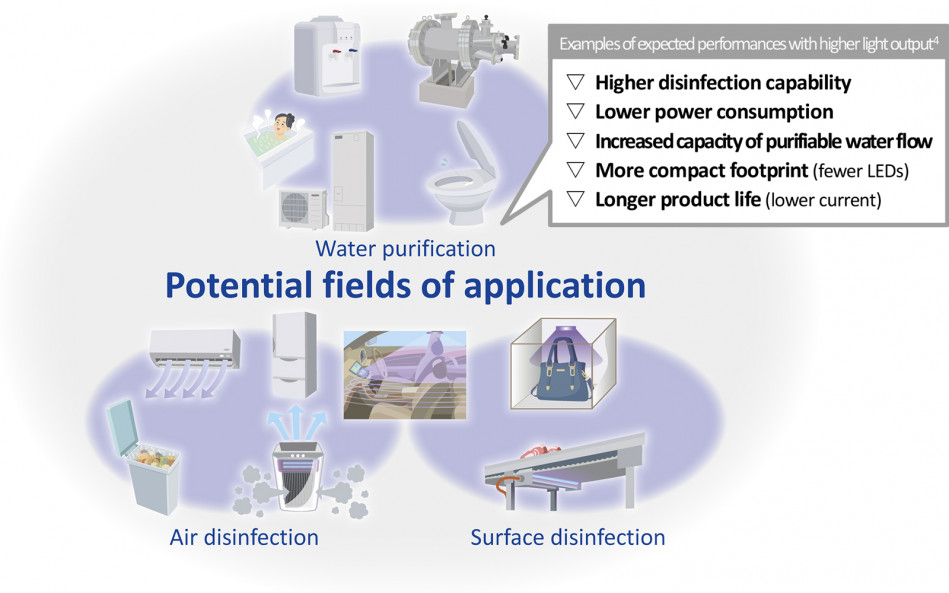

Kiyosu, Japan, April 22, 2024: Toyoda Gosei Co., Ltd. has developed deep ultraviolet (UV-C) LEDs with light output that is among the highest in the world.1 UV-C is used in disinfection as it destroys viral and bacterial DNA structures and inhibits their replication. As an alternative light source for mercury lamps used for disinfection, improved performance of UV-C LEDs has been expected. Sample sales of Toyoda Gosei’s high performance LEDs will begin internationally from April 2024,2 to promote their wider use for disinfecting water, air and surface.

Compared with mercury lamps, UV-C LEDs are environmentally-friendly as it is mercury-free, more compact, and have a longer life. These advantages promoted their wide use in devices for disinfecting air and surfaces during the Covid-19 pandemic. Since they differ from lighting LEDs in composition, however, light output has been still limited. For water purification plants and other situations where high disinfection performance is needed, mercury lamps are still used.

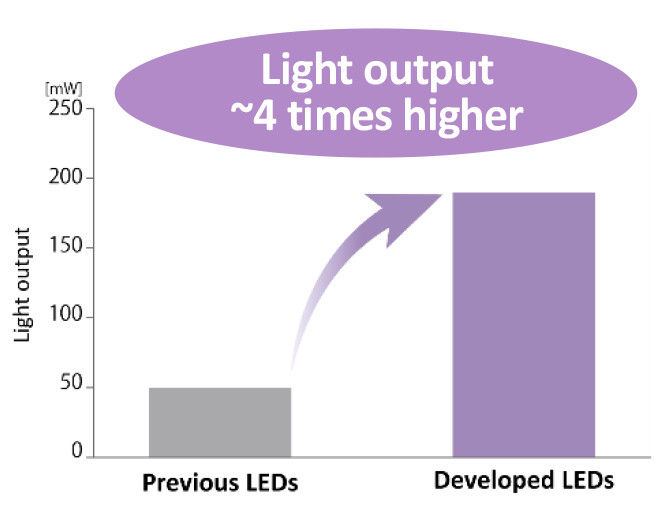

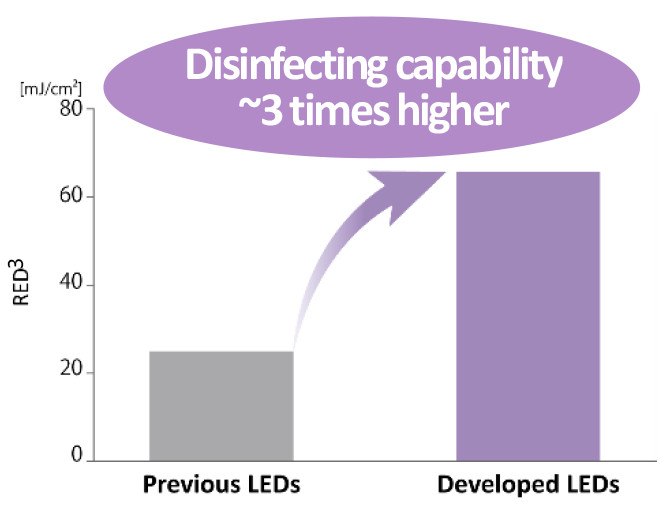

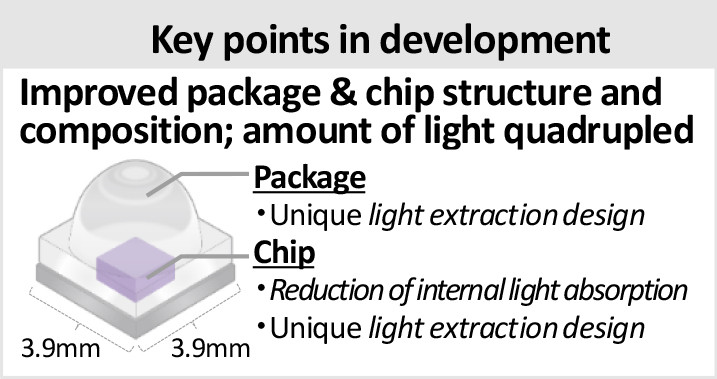

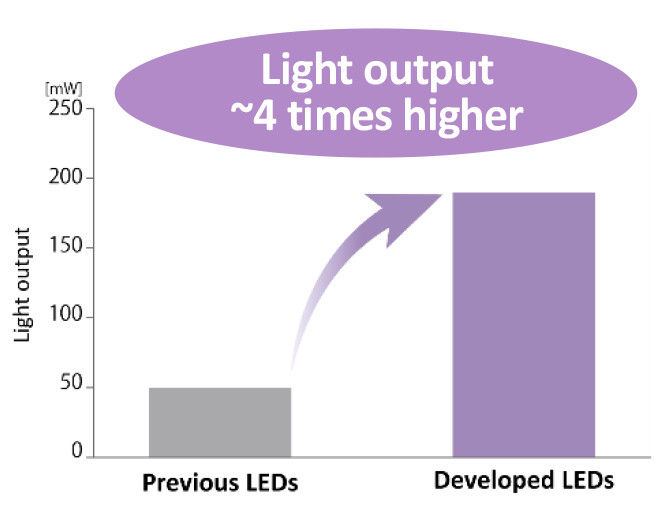

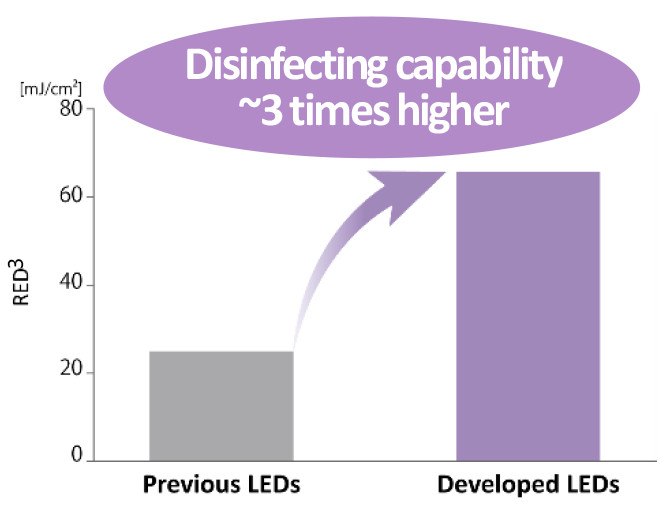

Toyoda Gosei has leveraged its expertise in crystallization and design of blue LEDs for lighting, and successfully developed UV-C LEDs that achieve light output at the level of 200 milliwatts with a single chip when driven by a current of 350 milliamperes. Improvement of the LED structure and composition quadrupled the amount of light that can be extracted. Enhanced LED performance including disinfecting capability of about three times higher will expand their applicable areas including a future alternative to mercury lamps, contributing to more hygienic and safer living.

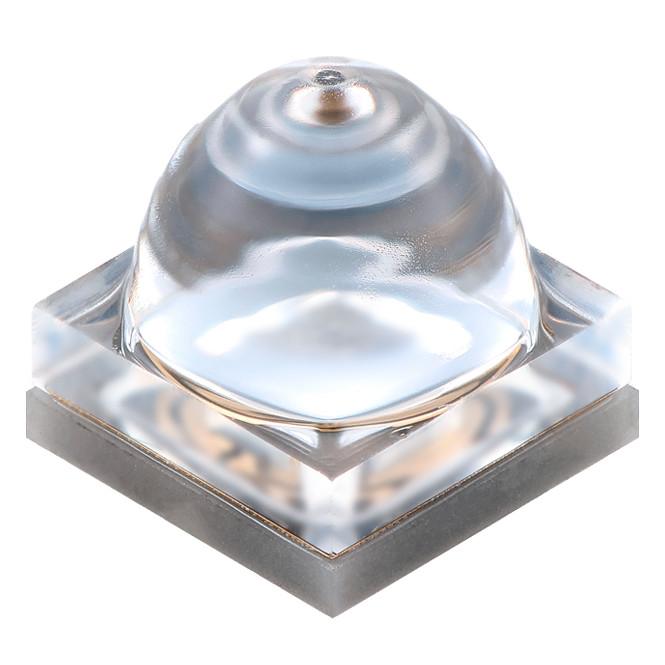

High power UV-C LED

(Two types developed:

Wide and narrow light distribution)

1 As of March 31, 2024. Toyoda Gosei survey

2 Sample sales start in Japan, China, and South Korea in April 2024. Successive starts are planned for other regions.

3 Reduction Equivalent UV Dose is an indicator of disinfection performance

4 Expected performances also depend on disinfection device specifications and conditions