News

December 24, 2025

Toward Decarbonization and Resource Circulation for Rubber Products

Toyoda Gosei Launches Automotive Parts with High Recycled Rubber Content

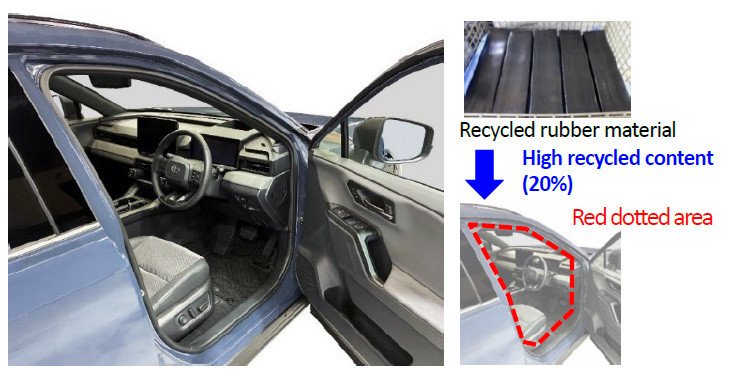

Kiyosu, Japan, December 24, 2025: Toyoda Gosei Co., Ltd. has commercialized automotive parts (weatherstrips) that incorporate a high percentage of recycled rubber material. Beginning with their adoption in Toyota Motor’s new RAV4, the company will expand application of this recycling technology to further contribute to decarbonization and resource circulation.

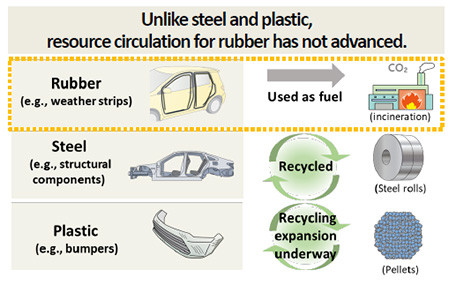

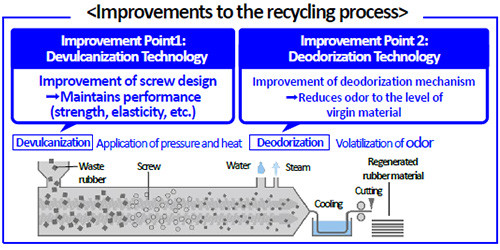

While resource circulation has advanced for materials such as steel and plastic, rubber remains difficult to recycle, and waste rubber is usually incinerated for thermal energy recovery. Recycling rubber requires devulcanization, a process in which heat and pressure break the sulfur bonds that give rubber its elasticity. However, this process also breaks other chemical bonds, resulting in reduced strength and leaving behind characteristic odors—long-standing challenges in rubber recycling.

By continuously improving our proprietary devulcanization technology, Toyoda Gosei has enhanced the quality of regenerated rubber material derived from waste rubber. These advancements have enabled us to increase the proportion of recycled material usable in automotive parts from less than 5% to 20%.*1 It has been recognized in a Toyota Motor’s Project Award.

Toyoda Gosei is advancing development with the aim of applying its technologies not only to synthetic rubber used in products such as rubber hoses,*2 but also to natural rubber, which is used in much larger volumes. Furthermore, by collaborating with automakers and other partners to establish a circular system that collects and regenerates rubber from end-of-life vehicles, the company aims to lead the industry in rubber recycling.

<Automotive parts for RAV4 using high recycled rubber content>

<Challenges in the automotive industry>

*1 At our Morimachi Plant, we have obtained ISCC PLUS certification, an international standard for sustainable products, and are applying the mass balance approach.

For details, please refer to the press release issued in April 2023.

*2 Parts made of ethylene–propylene rubber, the same type of rubber used in weather strips.