“Visualization of noise” for increased

quietness in vehicle interiors

2024.07.05

- HOME

- Features & Topics

- “Visualization of noise” for increased quietness in vehicle interiors

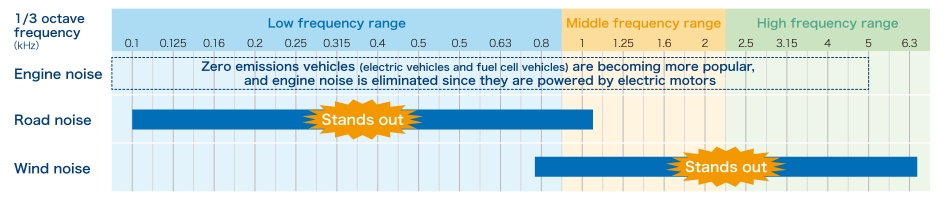

Zero emissions vehicles that do not emit CO2 during operation (electric and fuel cell vehicles) are becoming more popular. These vehicles are much quieter than gasoline engine vehicles since they are powered with electric motors and thus have no engine noise. This also means, however, that wind noise during driving becomes more noticeable. Weatherstrips, which serve to prevent the infiltration of noise and rainwater into the vehicle interior, need greater than ever sound insulating properties.

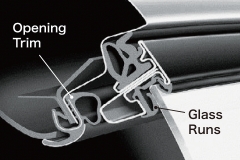

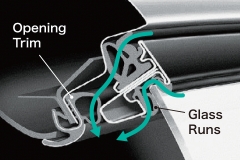

Toyoda Gosei, which has one of the world’s top shares in automotive weatherstrips, has established an original performance assessment system that incorporates “visualization of noise” to pinpoint the source of noise during vehicle operation. This has led to the development of opening trims1 and glass runs2 with higher sound insulating properties than previous products. Use of these products on Lexus and other luxury vehicles is growing, contributing to improved quietness and comfort in the interiors of these vehicles.

1 Sealing parts that are attached to the body side of door openings

2 Sealing parts attached to the window frame

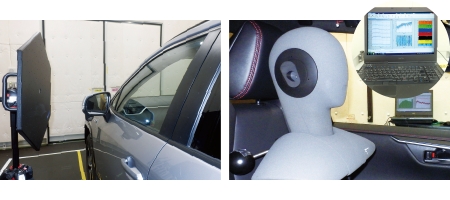

01Original assessment system

“Visualization of noise” means measuring the noise of the tires against the road and noise that is transmitted from around the window glass and expressing them in a way that can be seen. With previous test methods that used fixtures that mimic individual weatherstrips and door structure (bench evaluations performed with parts that constitute an automobile installed on a workbench), not all of the sounds that come into the vehicle interior during driving could be picked up. We decided that previous assessment systems had limitations due to their noise input methods, and so shifted to assessment methods with actual vehicles. We installed a dummy head that could measure noise in the vehicle interior during vehicle operation, and developed an environment where different noises were picked up in real time with multiple microphones. For microphone placement in particular, an issue was that differences occurred in the range of noise picked up. We made repeated attempts to apply assessment software used in the home electronics and other industries that is sensitive to noise and vibration. Through this process of trial and error, we established a number of different measurement and assessment methods specialized for weatherstrips.

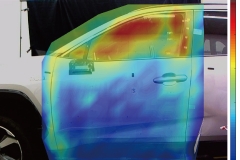

Using this assessment method, we analyzed the true nature of the noise while repeating measurements and assessments in our own experiment building and test course. The results of the analysis showed that wind noise and road noise from the entire door accounted for a large proportion of noise in the vehicle. The data also showed where the noise occurred. Understanding the nature of the noise spurred development with the aim of further improving quietness.

■New assessment system

■Visualization of sound

Noise source speakers were installed in the vehicle interior to measure sound leakage around the vehicle doors in real time. The sources of noise could be identified in a short time with sound visualization mapping technology.

■Relationship between sound and frequency

02New attempts in design

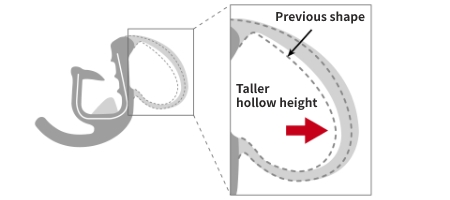

Opening trim serves the role of sealing the gap between the body and door, but the negative pressure3 that occurs during high-speed driving pulls the door, creating a gap that generates wind noise. To prevent such gaps from occurring even during high-speed driving, we attempted to enlarge the hollow portion inside the opening trim, but ran into two issues. The first was that when the outer hard surface protective layer (solid coating) was made flexible to match the movement of the hollow portion, it had a poor appearance and had difficulty maintaining a shape stable. The second was that the door became harder to close.

The solid coating serves to increase durability so that the hollow portion will not wear and break when people get in and out of the vehicle. To enlarge the hollow portion, we got rid of this solid coating and instead used a surface treatment agent to protect the opening trim. In developing that material, we clarified the physical properties of about 10 different ingredients and discovered the optimal mixture. This enabled us to achieve improved quietness while maintaining the surface durability.

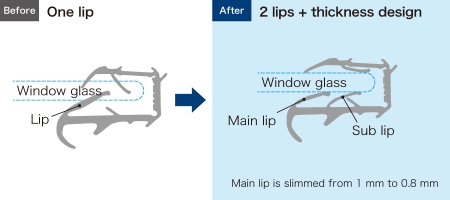

■Cross section of opening trim

Glass runs serve the roles of allowing the window glass to go up and down smoothly, and sealing the gap with the door. However, like opening trim, a gap is produced during high-speed driving and wind noise occurs. The position of the lip portion of the opening trim is the determining factor is cutting that noise, and we decided to add another lip to the single lip on previous products. To form two lips in a limited, small space, we modified the shape and other aspects. This successfully suppressed the high and middle frequency noise (2–3 decibels) that makes up wind noise at a speed of 100 km/h, giving these glass runs superior sound insulating properties.

3 A state in which pressure in a given space is lower than the surrounding pressure

■Glass run (double lip + thickness design)

03Bringing greater silence to vehicle interiors

After successfully reducing wind noise (noise in the middle to high frequency range) in opening trim and glass runs with higher sound insulating properties, the remaining issue is road noise (low frequency range). Going forward, we will raise the accuracy of assessments by combining assessment systems using simulation technology with actual measurements on a test course to further speed development. By leveraging our knowledge of polymer materials to also develop materials that have higher sound insulating performance, we will continue efforts to raise the added value of sealing parts.

Voice of developer

We want to contribute to quieter and more comfortable vehicle interiors

With the spread of electric vehicles, there is a rising need for quietness in vehicle cabins. Sealing parts are expected to play greater roles in this. Actual vehicle assessment methods and simulations that collect stable data without being affected by weather or wind direction will lead to shorter development periods and lower costs. By taking advantage of these strengths and being early to launch next-generation sealing parts on the market, we want to contribute to the realization of more comfortable zero emissions vehicles.

Masatoshi Nojiri, Group Manager, WS Development Division